AMOLEA™ Fluorosolvents: Advantages and Applications of Next-Generation Precision Cleaning

Reading Time: 3 minutes

Precision cleaning is frequently defined as the removal of particles less than a micron. This cleaning is required prior to assembly to ensure the safety and integrity of technically sophisticated parts and components. These include parts used in the automotive, aerospace, medical and electronics industries that could impact product performance if not properly decontaminated.

In fact, many components used in critical applications must be inspected to demonstrate they meet regulated cleaning requirements. Standard IEST-STD-CC1246E Product Cleanliness Levels from the Institute of Environmental Sciences and Technology provides methods for specifying and determining product cleanliness levels. In addition, there are many other industry-specific precision cleaning standards from organizations such as the International Organization for Standardization, Kennedy Space Center, Aerospace Industries Association, SAE International and the U.S. Food and Drug Administration.

Precision Cleaning With Fluorosolvents

There are a variety of precision cleaning solutions on the market, but many are harmful to the environment and some are even under EPA scrutiny. That’s why manufacturers are turning to cleaning solutions like fluorinated solvents, which clean parts efficiently and have a favorable environmental profile.

Fluorinated solvents are high-performance chemicals used for removing contaminants from high-value parts and components. Contaminants include solids, like particles and fibers, and residues such as oils and greases. Because fluorosolvents do not leave water spots or residue, using them doesn’t require follow-up cleaning processes.

Fluorosolvents have a low surface tension, which means they are better able to penetrate narrow spaces, cavities, and blind holes. They are ideal for cleaning a wide variety of substrates because they have good compatibility with metals, plastics, and elastomers.

Energy Efficiency

Fluorosolvents can be used in vapor degreasers, which require a small floor space and less energy than aqueous systems due to their shorter cleaning and drying cycles. Although cleaning with fluorosolvents uses heat, their boiling point is significantly lower than water, using less energy and time.

Because fluorosolvents are exceptionally stable, you can use them many times over without pH monitoring and stabilizer addition. This provides a lower cost per unit cleaned.

Environmental Advantages of AMOLEA™ AS-300 and AS-300AT Fluorosolvents

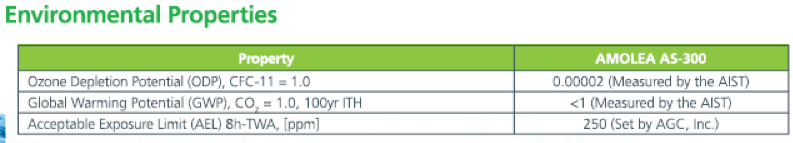

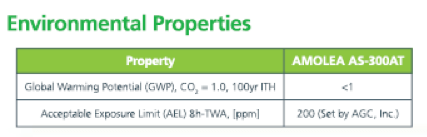

Our AMOLEA AS-300 and AS-300AT grades are next-generation nonflammable fluorinated solvents based on hydrochlorofluoroolefin (HCFO) chemistry. Thanks to this new technology, they have excellent cleaning solvency, are not regulated as hazardous air pollutants (HAP) and have a global warming potential (GWP) of less than 1.

The EPA’s SNAP program lists AMOLEA AS-300 and AS-300AT solvents as acceptable for electronics cleaning, metals cleaning, precision cleaning and coating diluents. Officially called the Significant New Alternatives Policy, SNAP is designed to review and certify substitute chemicals and technologies that are more environmentally friendly than their predecessors.

AMOLEA AS-300

AMOLEA AS-300AT

These solvents have an advantageous boiling point that enables less solvent loss. AS-300 cleaning agents also have no flash point and are nonflammable, making them safer for the working environment. The Kb values of AMOLEA AS-300 and AS-300AT are 44 and 118 respectively, which provide high solvency.

AMOLEA AS-300 and AS-300AT solvents are ideal replacements for hydrofluorocarbons (HFC) solvents and low-boiling-point HCFO solvents, as well as n-propyl bromide (nPB or 1-BP) and trichloroethylene, which are both undergoing risk evaluation under the EPA’s Toxic Substances Control Act (TSCA) and are at high risk of being banned in cleaning applications.

AMOLEA AS-300 and AS-300AT Applications

AGC customers around the world have successfully used AS-300 and AS-300AT grades to clean and degrease parts including:

- Precision parts

- Metal parts

- Aerospace parts

- Semiconductor equipment parts

- Electronic parts including PCB

- Optical components

- Medical device components

- Automotive parts

Other applications for these fluorosolvents include:

- Diluting silicone oils

- Diluting fluorine greases and oils

Access more information about AMOLEA fluorosolvents here.

To learn more about AMOLEA AS-300 and AS-300AT, contact an AGC representative.

English

English