Fluoropolymer Compounds: How to Select the Right PTFE Filler For Your Application

Reading Time: 4 minutes

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer of tetrafluoroethylene that is widely popular because of its numerous benefits that can be adapted for use across a variety of industries and applications. The unique properties of PTFE make it useful for both domestic and commercial applications. These properties include:

- A very high melting point of 327 °C

- Hydrophobicity

- Chemically inert

- Low coefficient of friction

- High-flexural strength

Why Filled PTFE Compounds?

Despite PTFE’s many advantages, it has one major disadvantage. Because it is highly flexible it can easily become deformed in applications involving pressure or heavy loads. However, adding filler to the compound can help resolve the issue while giving the compound advantages of both the filler and PTFE. The results is a fluoropolymer compound with enhanced performance.

Fluon+ Filled PTFE compounds are composed of pigments and fillers such as glass, carbon, graphics and metal powders (bronze and molybdenum disulfide). These molding powders offer enhanced wear resistance, creep resistance, thermal conductivity and electrical conductivity over virgin PTFE resins. Filled PTFE compounds also preserve several properties including low coefficient of friction, excellent chemical resistance and a wide service temperature range.

Selecting the Right PTFE Filler

So how do you decide which PTFE filler is right for your application? Read below as we break down the most popular PTFE fillers and performance advantages they can bring to your compound.

Glass Fiber

Glass-filled PTFE compounds are the most universally used. Adding glass makes the compound stronger and more durable while reducing flexibility and creep. It can be utilized at service temperatures from -268 °C to + 260 °C in chemical applications ranging from liquid oxygen to fuming nitric acid. It can also be used in severe wear pads for railway cars and for self-lubricating compressor rings for non-aluminum cylinders. Similar to virgin PTFE, glass-filled PTFE is also chemically inert.

Ideal applications for glass-filled PTFE

- Self-lubricating bearings

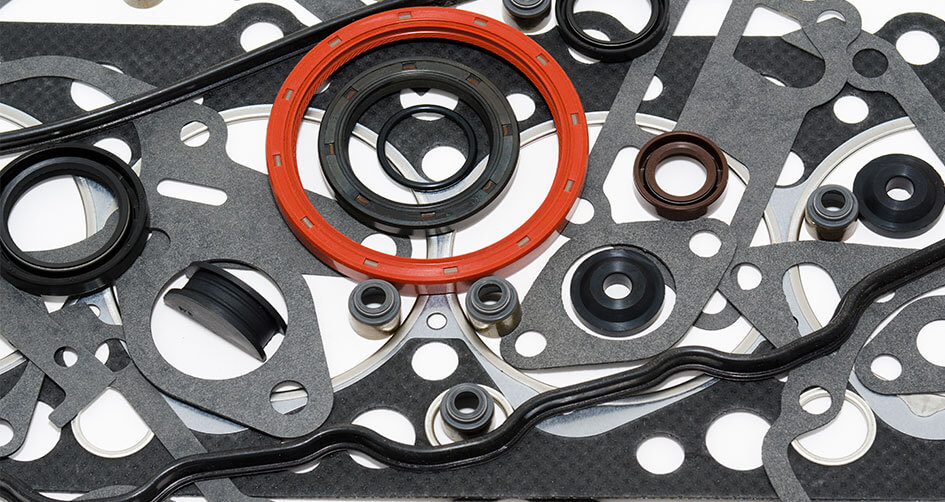

- Gaskets (static-dissipating, other)

- Seals (all types)

- Compressor rings

Molybdenum Disulfide (MoS2)

Adding molybdenum disulfide (MoS2) filler to your PTFE compound results in a harder and more slippery material. MoS2 is often used together with glass or bronze resulting in improved compression and wear resistance. In addition, it has a low coefficient of friction and helps to reduce torque on start-up.

Ideal applications for molybdenum disulfide-filled PTFE

- Self-lubricating bearings

- Piston rings and seals

- Big-billet/skived sheet

Graphite Powder

Graphite-filled PTFE imparts similar benefits to carbon-filled PTFE but does not improve wear resistance the way carbon-filled PTFE does. Graphite offers excellent self-lubricating properties and lowers the coefficient of friction. When combined with carbon, glass or both the compound imparts benefits of all 3 additives.

Ideal applications for graphite-filled PTFE

- Self-lubricating bearings

- Gaskets (static-dissipating, other)

- Seals (all types)

- Rings (V, O, back-up)

Bronze Powder

Ideal for applications that demand good thermal and electrical conductivity, bronze-filled PTFE is a great choice for bearings, seals and valve seats/liners used in applications like vehicle engines. While adding bronze to PTFE also improves wear resistance, it also reduces non-stick properties and chemical inertness of the PTFE.

Ideal applications for bronze-filled PTFE

- Self-lubricating bearings

- Seals (all types)

- Valve seats/liners

Minerals

Mineral-filled PTFE is often used for applications in the medical, pharmaceutical and food processing industries. Adding minerals to PTFE offers excellent load and wear resistance as well as good chemical resistance. It is FDA compliant and can withstand strict sanitization requirements. Mineral-filled PTFE can be combined with brass, bronze, steel, stainless steel and aluminum to achieve additional properties.

Ideal applications for mineral-filled PTFE

- Self-lubricating bearings

- Gaskets (static-dissipating, other)

- Seals (all types)

- Compressor rings

- Bushings

- Wear pads

- Trust washers

Polyester

Polyester-filled PTFE compounds exhibit superior heat and wear resistance as well as dimensional stability and corrosion resistance for molded or extruded parts. Choosing a highly crystalline polyester filler for the PTFE compound will also provide good creep resistance and excellent load-bearing capacity. This makes them ideal filler compounds to help increase the service life of bearings, seals, rotors and other parts in demanding applications.

Ideal applications for polyester-filled PTFE

- Self-lubricating bearings

- Compressor rings

- Big-billet/Skive sheet

- Seals

- Rotors

Polyphenylene Sulfide (PPS)

Polyphenylene sulfide (PPS) improves the wear and abrasion properties of PTFE. It also has high thermal resistance and excellent mechanical and extrusion resistance making it good for use in precise tolerance machined components such as backup rings. It has excellent chemical resistance and no known solvents below 200 °C (392 °F).

Ideal applications for PPS-filled PTFE

- Self-lubricating bearings

- Gaskets (static-dissipating, other)

- Compressor rings

Polyimide

Polyimide refers to a class of synthetic polymers. When added to PTFE, polyimide creates a compound that is low in friction and non-abrasive. Because of these characteristics, polyimide-filled PTFE is ideal for applications involving softer mating surfaces like steel, aluminum or other plastics.

Ideal applications for polyimide-filled PTFE

- Self-lubricating bearings

- Compressor rings

- Piston rings/seals

- Big-billet/Skive sheet

Stainless Steel

Stainless steel-filled PTFE is ideal for applications using steam and hot liquids because it works well at high temperatures. In addition, it enhances the strength and load bearing capabilities of the PTFE compound to which it is added. This type of PTFE is suitable for use in both mechanical uses as well as food and drink industry uses that require FDA compliance. It is extremely hard wearing to the point that it can cause wear on adjacent surfaces.

Ideal applications for stainless steel-filled PTFE

- Gaskets (static-dissipating, other)

- Seals (all types)

- Valves Seats/liners

In its natural state PTFE is an incredibly versatile material with many performance benefits. Adding fillers can help overcome its disadvantages while adding performance properties to the compound. By having an understanding of the performance properties that your application requires you’ll be able to select the right filler for your compound.

AGC’s Fluon+ PTFE compounds are produced in an environmentally friendly manner. They are easily processed in automatic molding equipment and are used primarily in automotive parts. Non-pelletized compounds are used in applications that demand the highest mechanical strength. To learn more about creating the right PTFE compound for your application contact an AGC product expert.

English

English