The importance of silica quality in providing accurate and consistent HPLC results

Reading Time: 3 minutes

The most important factor that influences accurate and consistent HPLC results is quality of the packing material. AGC has been producing the highest quality spherical silica gels for decades with our proprietary process under the brand name M.S. GEL. They offer the following benefits for both separation and purification:

- High purity

- Perfect spherical shape

- Uniform pore structure

- Narrow pore size distribution

- Narrow particle size distribution

- Strong mechanical stability

- Easy scale-up

Purity

It all starts with purity. Purity is so important in chromatography because impurities affect the columns’ HPLC performance by changing the retention strength and producing badly tailing peaks. The surface of microspherical silica contains many silanol groups that can react and bond with impurities such as metals. Highly pure silica gels prevent this from happening. M.S. GEL silica is SiO2≥99.99%. The raw materials we use are very pure, and our process is very tightly controlled to prevent the introduction of foreign impurities.

Spherical Shape

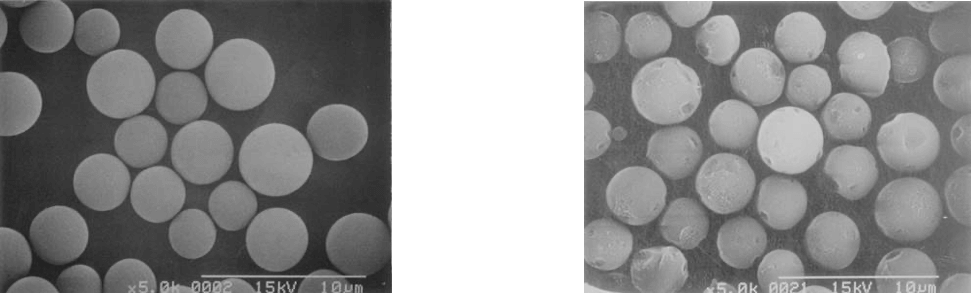

M.S. GEL particles are perfectly spherical, which enables more uniform packing with less channeling effect. This leads to lower back pressure, better separation and purification performance and longer product life. This is even more noticeable when compared with irregular silica. Column packing and HPLC results are much better with spherical silica because the particles can be packed more compactly.

Pore Structure

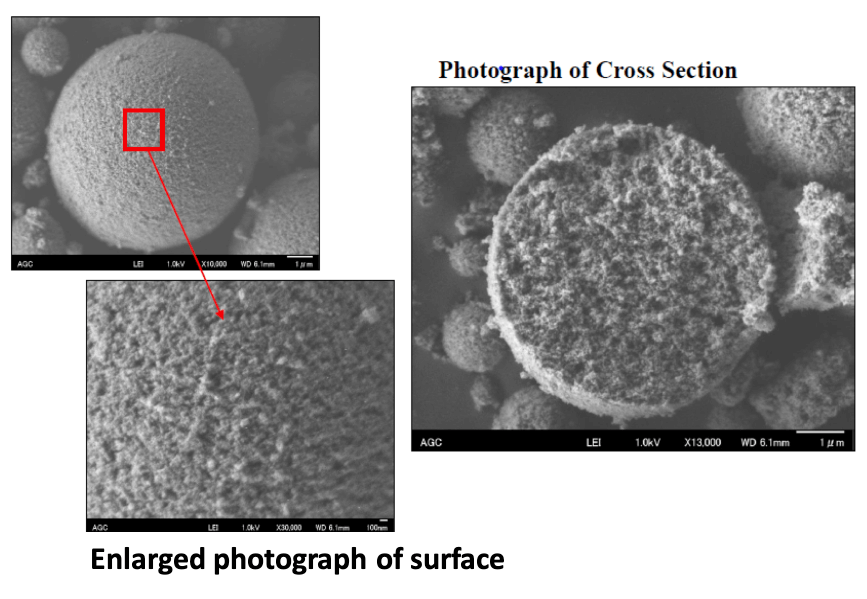

As you can see below, the M.S. GEL particles are very spherical and have excellent pore size uniformity. The photo on the lower left is an enlarged picture of the surface. You can see the uniform porosity. The picture on the right is a cross section of an M.S. GEL particle that illustrates uniform porosity inside the particle as well. This uniform porosity and a narrow pore size distribution provide uniformity throughout the particle and consistency among particles. M.S. GEL is available in a wide selection of particle and pore sizes.

Narrow Pore Size Distribution and Lot-to-Lot Reproducibility

M.S. GEL’s high specific surface area and narrow pore size distribution enable higher loading capacity. There are many grades available for specific applications, with pore sizes up to 1500 A. This product consistency and extensive portfolio make it possible to easily scale up from analytical to preparative HPLC. The narrow particle size distribution of M.S. GEL makes it a very suitable packing for preparative chromatography. Consistency and repeatability mean less down time and better analytical data. Batch-to-batch consistency is very stable based on surface area and carbon content.

Mechanical Stability

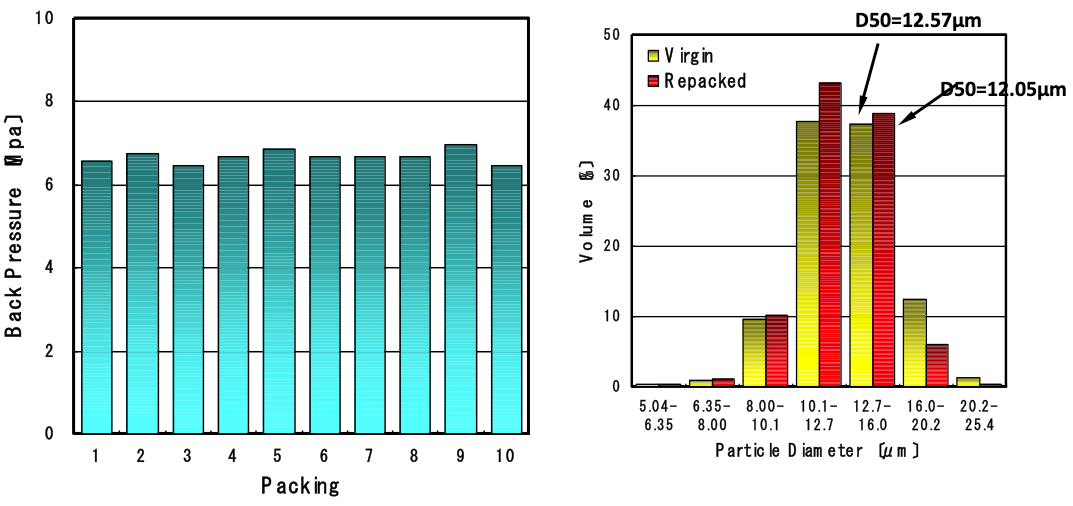

M.S. GEL microsphere particles have high mechanical stability. The chart below shows the change in back pressure after repeated packing. This consistency is attributed to the strength of the gel particles. The graph on the right charts the particle distribution before and after packing. Note how the peak shapes are very similar before and after packing. This proves there is no particle deformation because of particle strength.

For more information on which M.S. GEL grade is best for your chromatography application, visit our M.S. GEL web page or contact an AGC representative.

English

English