AGC Chemicals Americas

-

English

English

- Documentation

- Resources

- Blog

-

Customer & product inquiries: 1-800-424-7833

Customer & product inquiries: 1-800-424-7833

AGC Chemicals Americas

English

English

EXTON, Pa., April 30, 2018 – PEEK (polyether ether ketone) thermoplastics have long been known for their high strength-to-weight ratios and excellent heat tolerance. Now AGC Chemicals Americas, Inc., offers enhanced PEEK with specialty fluoropolymers to improve its impact and wear resistance, flexibility and electrical properties. AGC will introduce JBU-900X modified PEEK at booth S35053 at NPE2018: The Plastics Show.

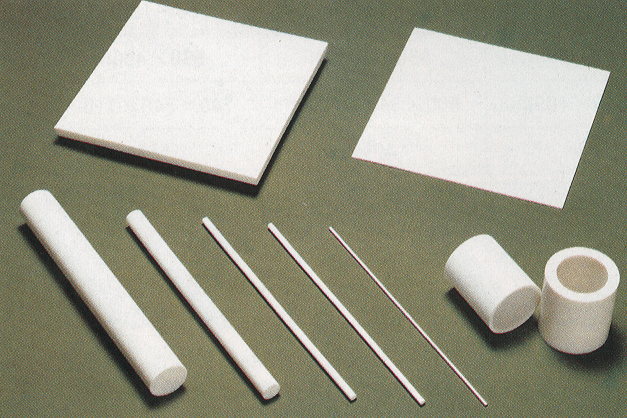

JBU-900X modified PEEK can be used to produce stock shapes such as sheets, rods, tubes, gears, casings, wire and cable insulations, and film that better withstand demanding operational conditions. Compared with standard PEEK, JBU-900X modified PEEK reduces the occurrence of delamination by moldings during processing. It can be processed by extrusion molding, injection molding and pressure molding. JBU-900X also demonstrates a lower dielectric constant than standard PEEK at high temperatures up to 200 °C.

In addition to JBU-900X modified PEEK, AGC will feature the following fluorochemical solutions for the plastics industry:

Fluon® PFA EA-2000 resin, which features a built-in functional adhesive group that enables one-step processing with other polymers and metals.

Fluon ETFE LH-8000 resin, a lower-melting adhesive ETFE that bonds to dissimilar materials, such as polyamides, polyethylenes and metals, in many cases eliminating a tie layer, and can be used on conventional/non-specialized equipment.

Fluon AH-ETFE resins, which chemically adhere to dissimilar materials, reduce weight and are ideal for use in multilayer hose constructions.

Fluon ETFE AH-600, 700 and 800 resins, which are ideal for constructions that require excellent conductivity, chemical and permeation resistance, and protection against static buildup.

Fluon ETFE C88AXMP-HT, an ultra-heat-resistant grade that maintains performance characteristics at temperatures up to 200 °C that is ideal for industrial and automotive wire and cable insulation.

AFLAS® PM-1100 and PM-3000 peroxide-curable perfluoroelastomers (FFKMs) for fabricating components that will be exposed to ultra-high temperatures, and resist aggressive chemicals and provide excellent electrical insulation properties.

AFLAS CP-4000, a peroxide-curable FFKM pre-compound that offers outstanding resistance to chemicals, oils, solvents and extreme heat.

About NPE2018: The Plastics Show

As the world’s leading plastics trade show and conference, NPE® assembles the full array of products, tools, equipment and resources in one efficient venue, providing total coverage of the innovative solutions and emerging technologies that are shaping the future of plastics. NPE2018 will be held May 7-11, 2018 in Orlando, Fla. http://www.npe.org/

AGC Chemicals Americas is a global subsidiary of AGC Inc., a multinational corporation and one of the world’s largest manufacturers of glass, electronic displays and chemical products. Headquartered in Exton, Pennsylvania, including a state-of-the-art technology center, AGC Chemicals Americas maintains manufacturing operations in nearby Thorndale, Pennsylvania, a satellite sales office in Guaratingueta, Brazil, and warehouses located throughout North America. www.agcchem.com