-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

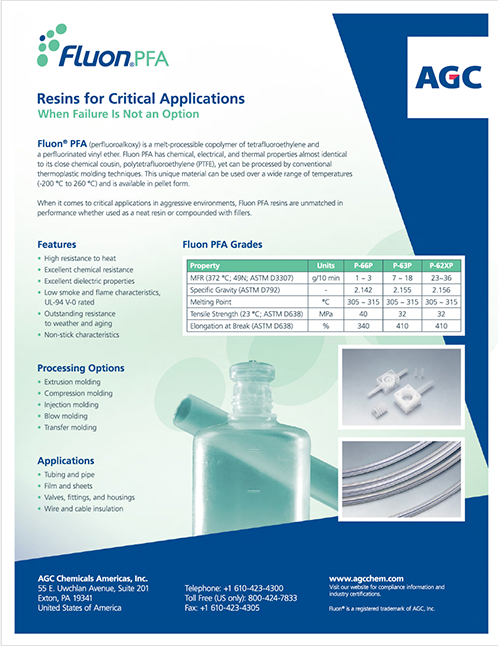

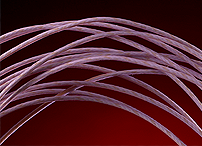

Fluon® PFA Resins

Maintains excellent chemical, electrical, mechanical and surface properties when used in a wide range of temperatures.

Copolymers that are made of tetrafluoroethylene and a perfluorinated vinyl ether.

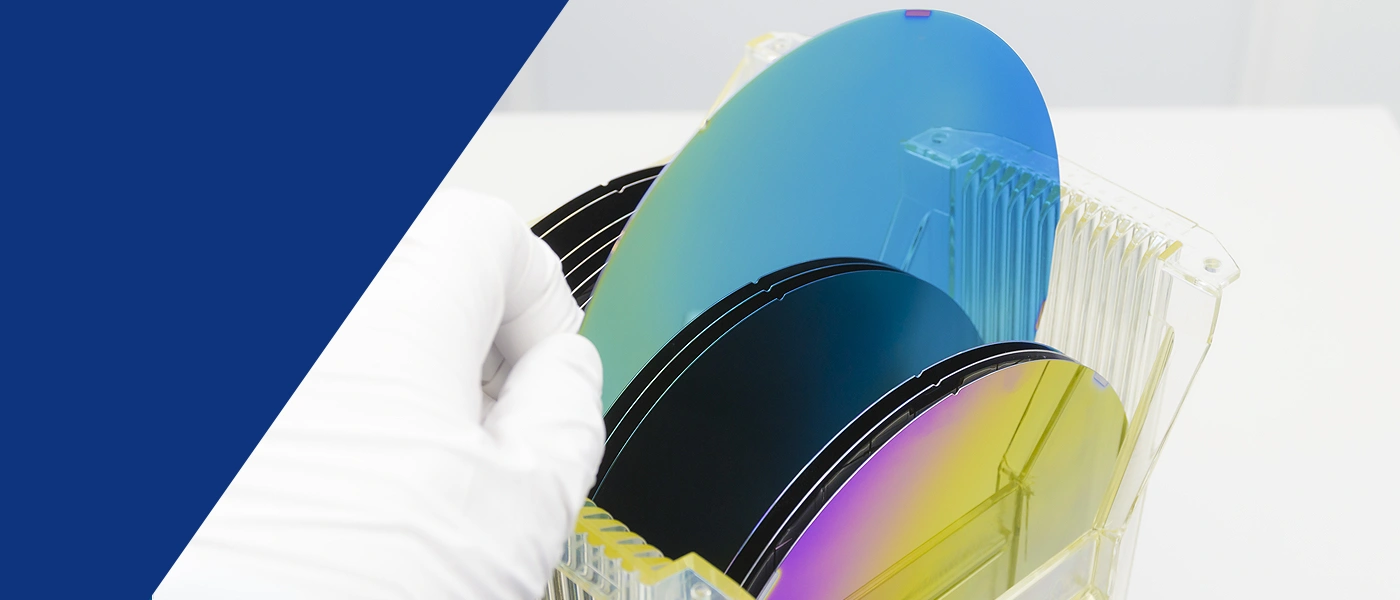

Fluon® PFA Resins are copolymers of tetrafluoroethylene and a perfluorinated vinyl ether. They can be used over a wide range of temperatures from extremely low to high (-200 °C to 260 °C) without losing excellent chemical, electrical, mechanical and surface properties.

PFA resins retain many inherent characteristics and similar properties of PTFE. However, PFA resins can be processed using conventional thermoplastic techniques including:

- Extrusion molding

- Injection molding

- Blow molding

- Electrostatic powder coating

With an oxygen index of 95% or better, these noncombustible resins can be used in various fields. They offer outstanding weatherability (no reduction or deterioration by direct sunlight, wind, rain and exhaust gas). In addition, their characteristics do not change when exposed to the outdoors for a long period of time. Fluon® PFA resin compounds are also available.

Manufactured without PFOA. For more information, click here.

Markets

- Used over a range of temperatures (-200 °C to 260 °C)

- Low smoke and flame characteristic conforming to UL 94V-0

- Weather and aging resistance

- Chemically stable material not attacked by most chemicals

- Low friction and non-stick characteristics

- Available in 1/8” pellets

- Tubing and pipe

- Film and sheets

- Valves, fittings and housings

- Wire and cable

- Blow-molded bottles

- Chemical processes

Click here to request an SDS sheet.

- Physical testing

- Analytical testing

- Environmental studies

- Material identification

- Thermal analysis

- Rheometry

- Microscopy

Call our fluoropolymer experts to discuss your specific needs.

Latest from the Blog

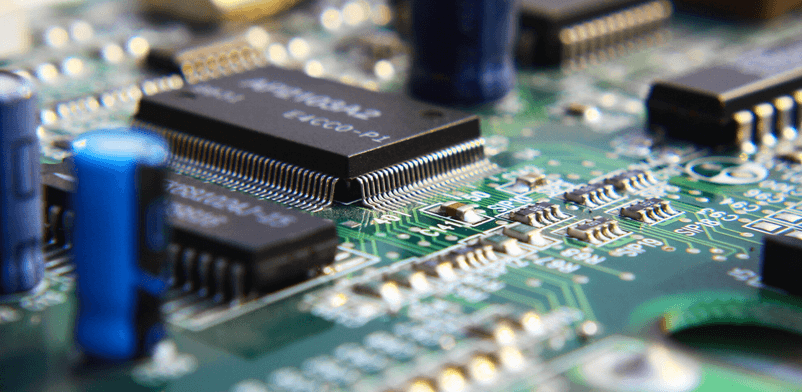

Fluon+™ PFA EA-2000 Adhesive Resins Serve as PCB Coatings to Speed Up Communication Rates in Autonomous Vehicles

By 2025, it is projected that the global market for partially autonomous and fully autonomous vehicles (AVs) will be $36 billion and $6 billion, respectively. These self-driving cars rely on sophisticated computer systems, sensors and other technology to safely navigate the road….

Read about this topic...Fluoropolymer Compounds Boost the Performance of Electric Vehicle Wiring

New fluoropolymer compounds for flat wire jackets enable automakers to move away from traditional rounded wires and reach 96 percent occupancy. Electric vehicle manufacturers are persistently working to develop ways to improve engine performance, raise output density, increase motor efficiency…

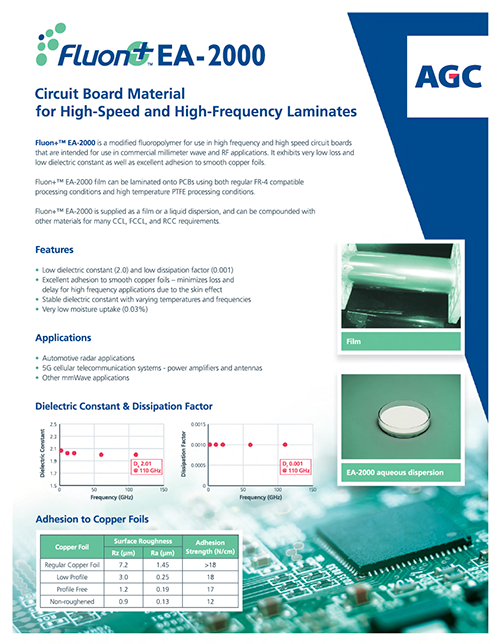

Read about this topic...Fluon+ EA-2000 Resin Meets Strict Demands of High-Frequency Printed Circuit Boards for 5G Technology

The new 5G cellular network is expected to become widely used by 2020. With already over 200 operators in more than 80 countries, 5G isn’t just on its way; it’s here. As a result, developers across the globe are working…

Read about this topic...