-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

RESIFA™ SUNSPERA Particles for Catalyst Support

These silica particles support catalysts in polyolefin polymerization and the synthesis of organic compounds.

A wide range of silica products for catalyst supports

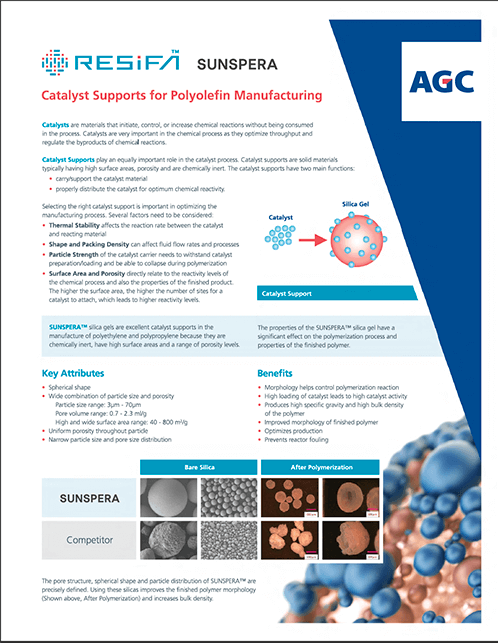

Polyethylene and Polypropylene Manufacturing

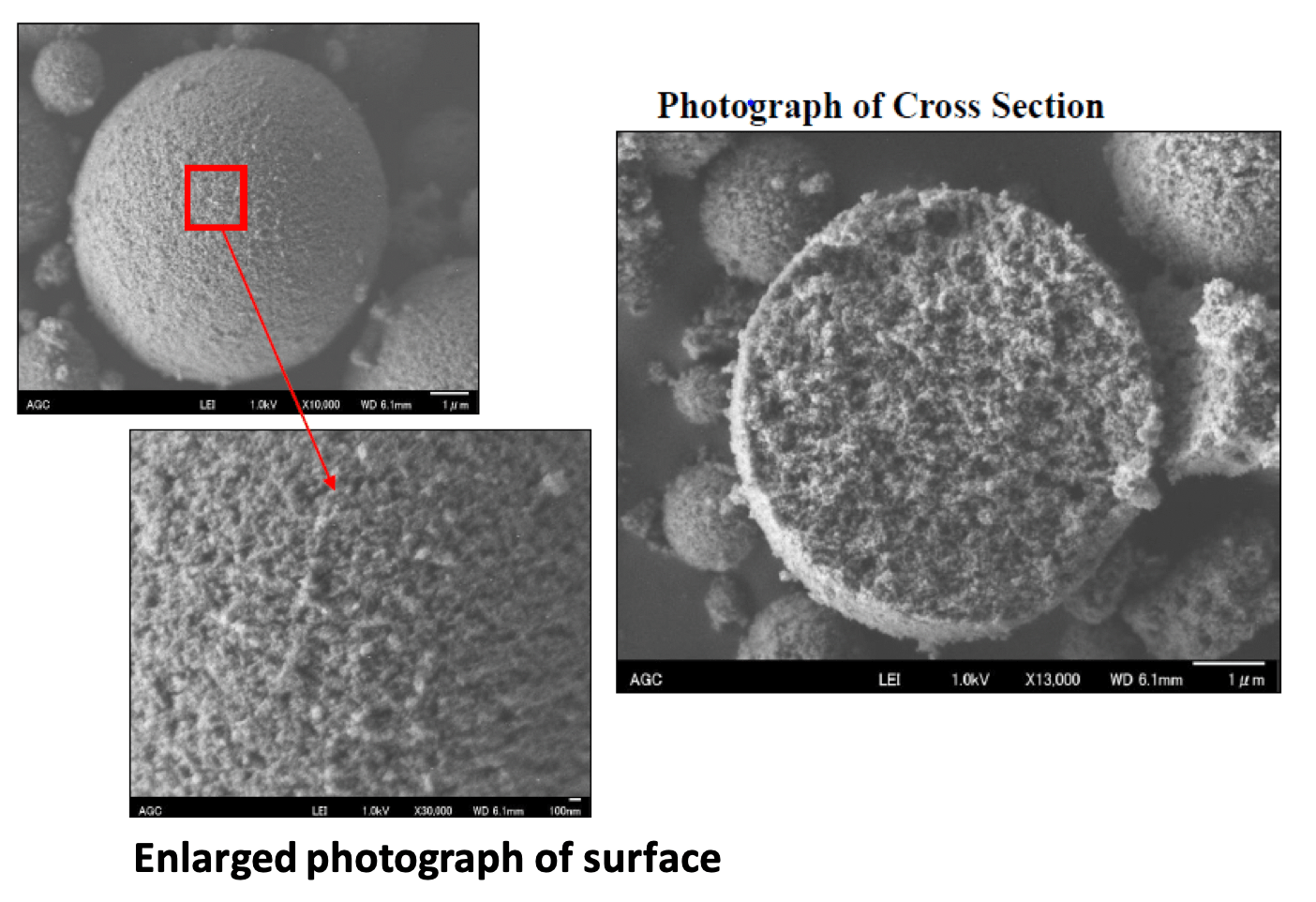

The properties of SUNSPERA silica gel have a significant effect on the polymerization process and properties of the finished polymer. SUNSPERA particles' pore structure, spherical shape and particle distribution are precisely defined. Using them as catalyst supports improves the morphology and increases the bulk density of the finished polymer resin. It also improves productivity. The SUNSPERA product line has grades suitable for liquid phase/slurry processes and gas phase processes.

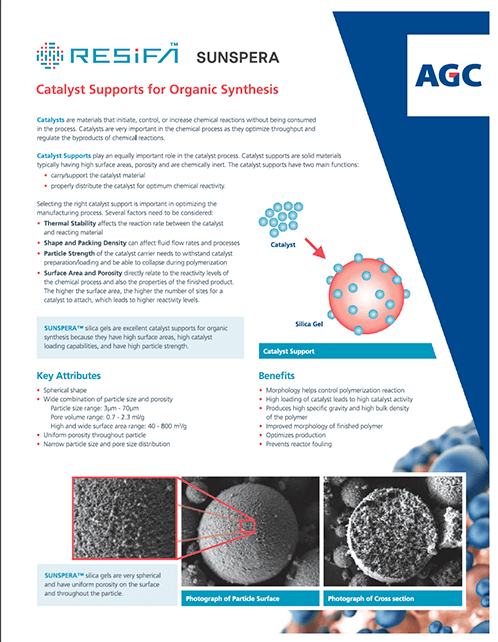

Organic Synthesis

SUNSPERA catalyst supports are also used in the organic synthesis of a wide range of organic compounds which require higher activity and particle strength. A range of grades are available with high surface areas, small pore volumes and high particle strength to meet these special requirements. The high surface area enables higher loading of the catalyst, which leads to higher activity.

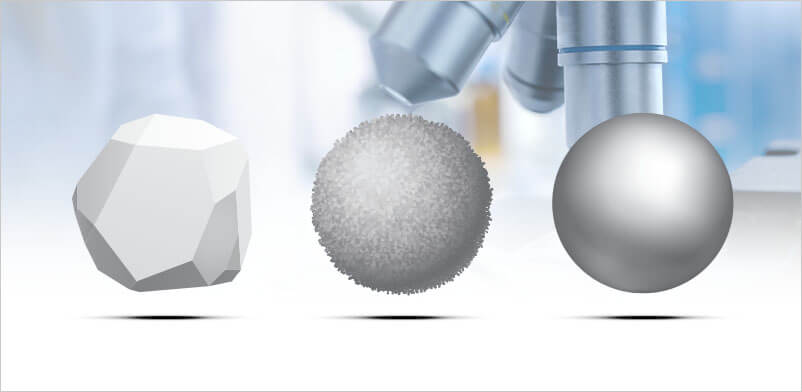

SUNSPERA silica is available in particle sizes from 3µm to 70µm, with surface areas ranging between 40-800 m2/g. The ability to select the particle size, pore size, and spherical structure of this fine silica product makes it possible to provide long lasting physiochemical-specific characteristics to specific media. The silica particles are very spherical, have a very uniform pore structure and a narrow particle size distribution. As an added benefit, SUNSPERA particles do not foul the reactor/process equipment.

Markets

- Spherical, uniform porosity, narrow particle size

- Particle sizes: 3 - 100 μm

- Pore diameters up to 1000 Å

- Surface area: 40-800 m2/g

- Improved morphology of finished polymers

- Optimizes production/higher catalytic activity

- Narrow particle distribution and no fine particles

- No fouling of reactor or processing equipment

- Developed for catalyst supports for manufacturing PE and PP resins using either liquid phase/slurry processes or gas phase processes.

- Special grades are available for organic synthesis used to manufacture a wide variety of organic compounds.

Click here to request an SDS sheet.

Contact our silica experts to discuss your specific needs.

Latest from the Blog

The importance of silica quality in providing accurate and consistent HPLC results

The most important factor that influences accurate and consistent HPLC results is quality of the packing material. AGC has been producing the highest quality spherical silica gels for decades with our proprietary process under the brand name M.S. GEL.

Read about this topic...Non-Porous Dehumidifying Membranes Easily Remove Moisture from Compressed Air Lines

Chemical separation is used to isolate components of a substance for analysis, reclamation or purification. Separation methods include dialysis, electrolysis, filtration, evaporation, distillation and chromatography.

Read about this topic...Specialty Materials/Specialty Intermediates: Building Blocks of Pharma and Agrochemical Products

Specialty Intermediates Most formulators associate AGC with product brands like Lumiflon, AFLAS and AsahiGuard that are based on fluorochemicals and perfluorohexyl chemistry. But AGC also develops and manufactures specialty materials. These “specialty intermediates” are the large and small fluorinated molecules…

Read about this topic...