-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

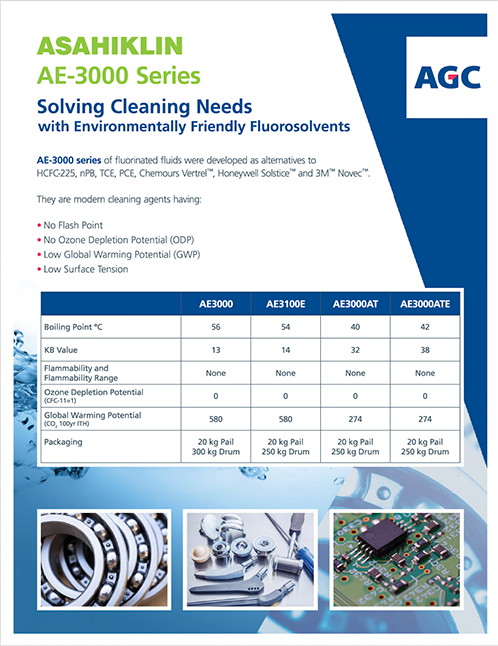

AsahiKlin™ AE-3000 Series Fluorinated Solvents

Environmentally sensible fluorinated solvents designed to replace halogenated solvents.

Precision cleaning solvent that can be used in vapor degreasing equipment

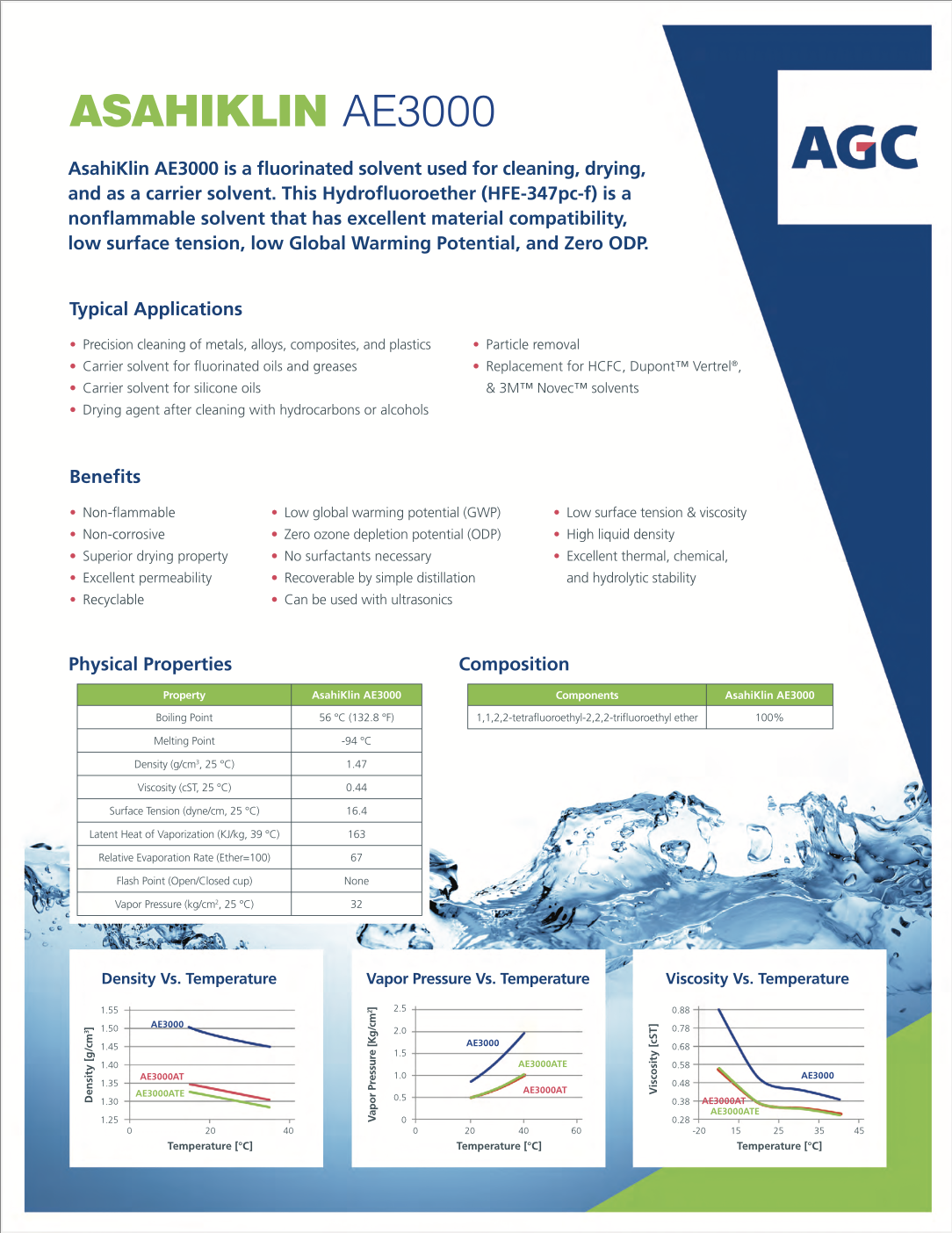

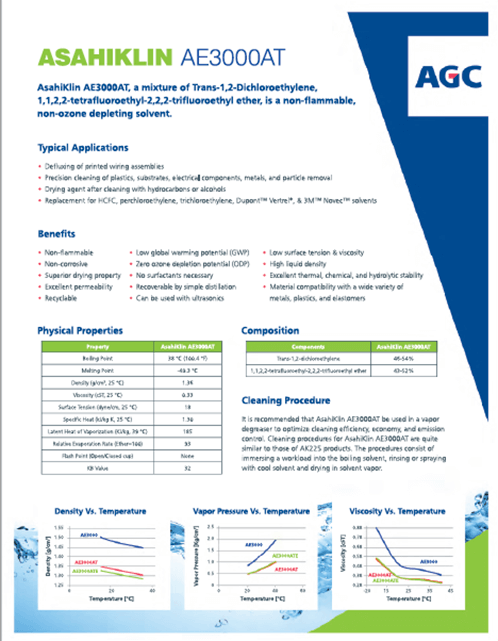

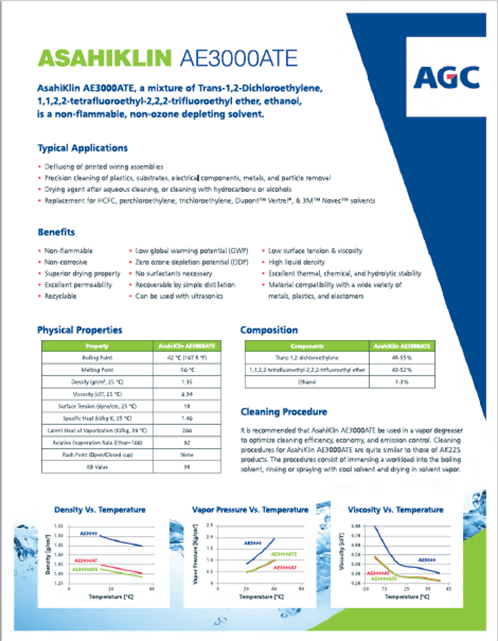

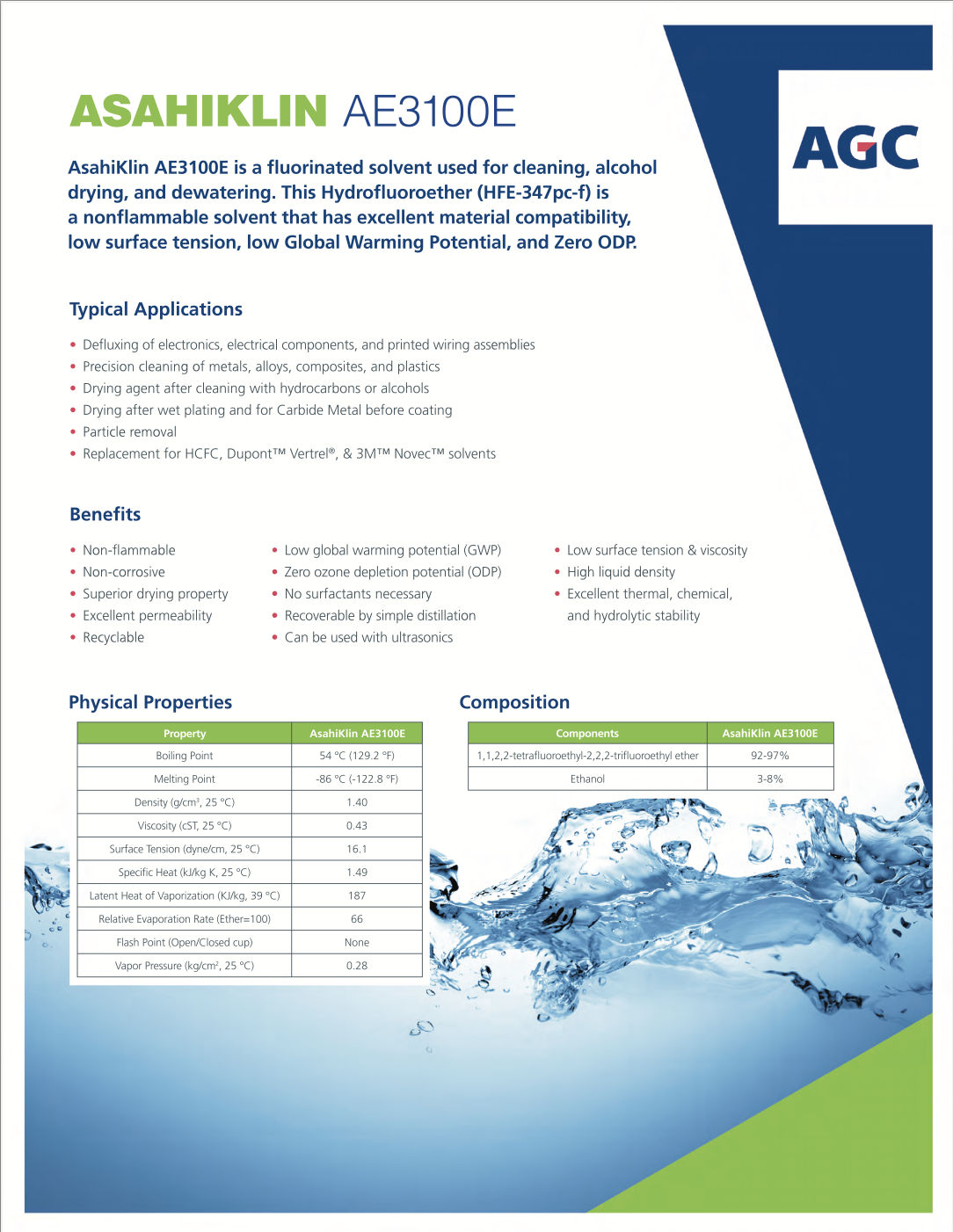

AGC created the AsahiKlin™ AE-3000 precision cleaning solvent to replace halogenated solvents with unfavorable environmental properties. AE-3000 cleaning agents have no flash point, no ozone depletion potential (ODP), low global warming potential (LGWP) and low surface tension.

AE-3000 solvents are approved for use as:

- Precision cleaning solvent

- Defluxing agents for electronic circuitry

- Carrier solvents for silicone and fluorinated lubricants

- Moisture displacement fluids

- They can also be used in most existing vapor degreasing equipment with little or no modification.

- ODP zero

- Minimal global warming potential

- Recyclable with distillation

- Chemically and thermally stable

- Nonflammable (no flash point)

- Broad compatibility with most plastics, elastomers, substrates and metals

- Cleaning of high-precision plastic and electronic components such as reflector glasses for laser printers, audio and video heads, and lenses

- Solvent carrier for silicone oils, hard disk lubricants, fluorinated greases and anti-rust agents

- Defluxing of printed circuit boards

- Drying element in aqueous system or as part of hydrocarbon cleaning process

- Refrigeration coolant and carrier solvent

- Precision cleaning of molded resin (components for copiers, cellular phones, camera parts, etc.)

- Dewatering of optical components

- Precision cleaning of delicate substrates

Click here to request an SDS sheet.

- Cleaning evaluation using vapor degreaser and/or benchtop ultrasonics cleaner

- Microscope inspection

- Solubility evaluation

- Acidity test

- Application development

- Chloride residue

- Composition by GC

- FTIR

- Moisture content

- NVR evaluation

- Material compatibility study (metal, plastic, elastomer etc)

Helpful Resources

Contact our fluoropolymer experts to discuss your specific needs.

Latest from the Blog

Advantages of Fluorinated Solvents Over Aqueous Cleaning

For many industries like medical device, aerospace and automotive, parts and components be cleaned and degreased before they are assembled or shipped. While many cleaning solutions exist on the market, regulations for cleaning chemicals are becoming more stringent. The United…

Read about this topic...Partnerships Expand Product Distribution Channels for Fluorosolvents and Fine Silica

These two partnerships allow for greater distribution of our product lines. Chem Logic promotes and provides technical support for fluorosolvents for high-reliability cleaning applications Our strategic partnership with Chem Logic as an independent sales rep helps sell our environmentally friendly…

Read about this topic...AMOLEA™ Fluorosolvents: Advantages and Applications of Next-Generation Precision Cleaning

Precision cleaning is frequently defined as the removal of particles less than a micron. This cleaning is required prior to assembly to ensure the safety and integrity of technically sophisticated parts and components. These include parts used in the automotive,…

Read about this topic...