-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

Fluon® PTFE Resins and Micropowders

Cost-effective fluoropolymer resins and micropowders that are widely used in many areas of modern life.

The Fluon® PTFE brand includes polytetrafluoroethylene resins and micropowders.

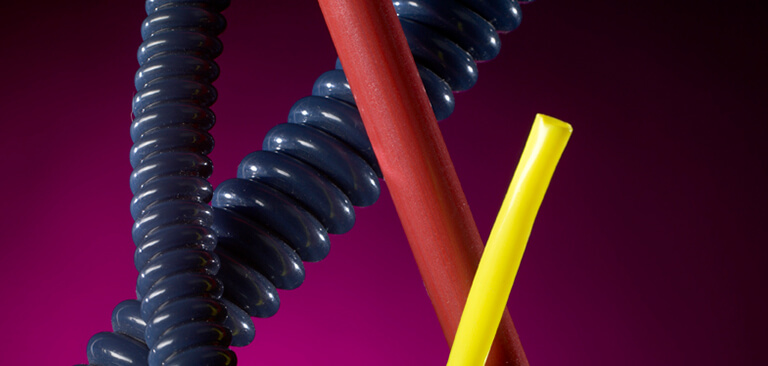

Highly cost-effective materials, Fluon® PTFE (polytetrafluoroethylene) resins are the most widely used fluoropolymers found in many areas of modern life. PTFE resin properties keep insulation thickness to a minimum while tolerating a wider range of temperatures (-180 °C to 260 °C) than other insulators.

Inert to almost all chemicals, PTFE resins also offer good resistance to most solvents. They are suitable for outdoor use with no detriment to properties from extended exposure to the elements. Kindly note that not all items may be commercially available so please contact us for specific grade information or to discuss your application for a recommendation.

Fluon® PTFE Resin Grades

To accommodate an ever-growing range of end-use products, PTFE resins are available in different grades

- Coagulated dispersions (CD): White, free-flowing powders made by coagulating dispersions of PTFE. Developed for paste extrusion into tapes, tubes, pipe liners and coated wires.

- Granular powders: Fine powders that are molded by first pressing and heating, then shaped by being cut or whittled into sheets, rods or billets. Available in a range of particle sizes and properties. Used for applications requiring superior mechanical or electrical properties.

- They have been developed for paste extrusion into tapes, tubes, pipe liners, and coated wires

Manufactured without PFOA! Click here (for info on CD) or here (for Granular).

Fluon® Micropowders

Fluon® PTFE Micropowders and FEP Micropowders are lubricants milled to a very fine powder while retaining excellent lubricity properties. These powders can be compounded in rubber and plastics or dispersed in liquids to improve friction and wear properties of the base material. Many grades are used in non-stick surface applications such as extreme pressure additives in oil and grease, and in solvent applications. PTFE and FEP lubricant powders offer great advantages over conventional anti-scuff agents in printing inks, permitting quick solvent release, faster printing speeds, and excellent print gloss.

Fluon® PTFE Resin Grades

- Coagulated dispersions: Suitable for extrusion of thin flexible sections, such as wire insulation, tubing and unsintered tape. They comply with the specifications of ASTM D4895 Type 1.

- Granular powders: Suitable for compression molding of billets, isostatic molding of intricate shapes, automatic molding of stock shapes, compounding with fillers, and ram extrusion of rod and tubing.

Fluon® Micropowders

- High thermal, chemical and weather resistance

- Improved wear resistance, lubricity, non-stick and frictional characteristics of host media

- Can be added to coatings that contact food and drink

- Excellent dielectric properties

Fluon® PTFE Resin Grades

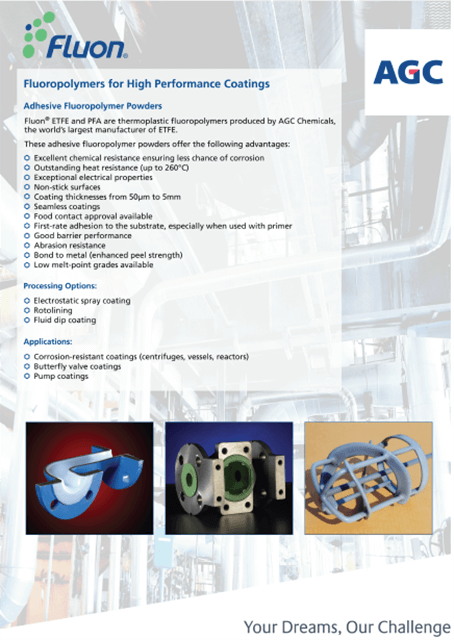

- Fuel hoses for automotive industry (CD)

- Textile membranes (CD)

- Tapes, tubes, rods and wire coatings (CD)

- Hydraulic hoses (CD)

- Slide bearing and valve components (Granular)

- Sheets, rods, billets and other general molded shapes (Granular)

- Gaskets and diaphragms in chemical process plants (Granular)

Fluon® Micropowders

- Anti-scuff agent for ink and paint

- Ski wax

- Coated cookware

- Thermoplastic additive

- Grease thickener

- Oil additive

Click here to request an SDS sheet.

Fluon® PTFE Resin Grades

Fluon® Micropowders

Fluon® PTFE Resins and Micropowders

- Physical testing

- Anaytical testing

- Environmental studies

- Material identification

- Thermal analysis

- Rheometry

- Microscopy

Call our fluoropolymer experts to discuss your specific needs.

Latest from the Blog

PTFE Micropowders Add High Resistance and Lubrication Properties to Thermoplastic Parts, Rubbers, Inks, Paint and Oils

PTFE micropowders evolved out of PTFE (polytetrafluoroethylene) coating materials that have been used for a long time in non-stick cookware. However, their uses extend beyond that. PTFE has many useful properties such as being resistant to water, heat, electricity, and…

Read about this topic...The Power of PTFE Powders as a Performance Additive

Thousands of products are formulated with fluoropolyer-based performance additives to enhance their properties. For example, Fluon® polytetrafluoroethylene (PTFE) micropowders provide desirable characteristics such as chemical resistance and improved lubricity, friction, and wear characteristics for thermoplastic parts and components. Manufactured through…

Read about this topic...PTFE Materials are a Beautiful Defense for Stadiums

In many sports, the best offense is a good defense. The same theory applies when designing architectural marvels, like stadiums. In fact, it is imperative to use materials that are both strong and stylish. This is because protecting arenas from…

Read about this topic...