-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

Fluon+™ Adhesive Grades

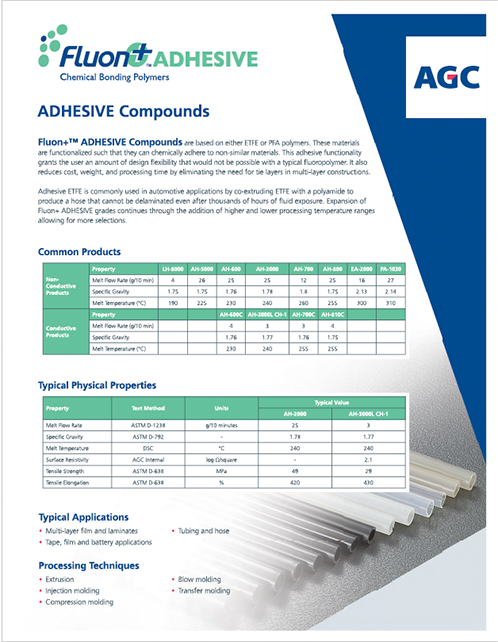

These adhesive grades are fluorinated adhesive resin compounds made with Fluon ETFE or PFA. They are used in applications requiring strong adhesion to polyamide polymers, especially nylon 12.

Fluoropolymer compounds made with Fluon ETFE or PFA.

Fluon+™ Adhesive resin grades are fluoropolymer compounds made with Fluon ETFE or PFA. They offer adhesive and dispersive properties and a level of compatibility with other materials not previously possible with fluoropolymers.

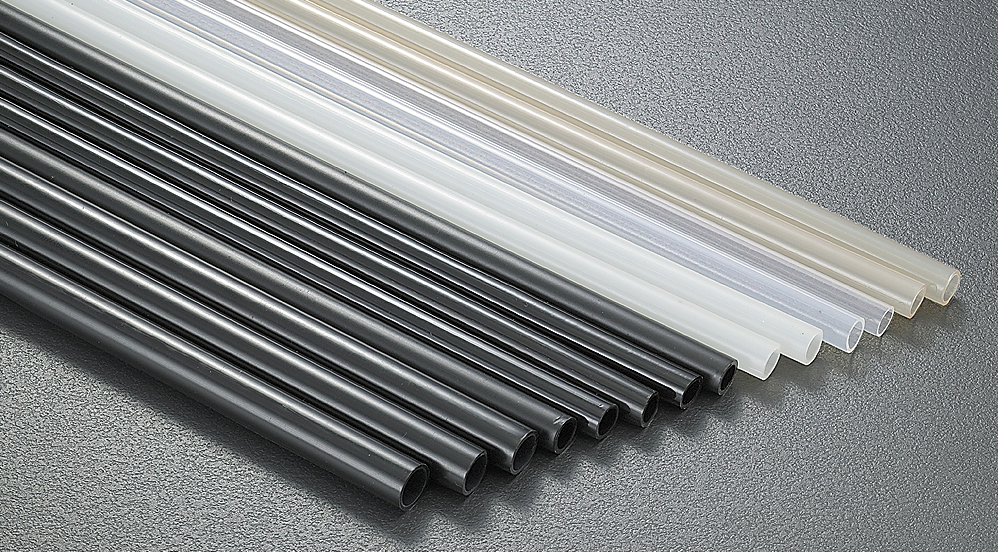

Fluon+Adhesive resin grades are used in applications requiring strong adhesion to polyamide polymers, especially nylon 12. These fluoropolymer compounds also exhibit high permeation resistance to many fluids and gases, especially automotive fuels.

Fluon ETFE AH-600, AH-700 and AH-800 adhesive resins chemically adhere to dissimilar materials, reduce weight and eliminate tie layers in multilayer constructions. They are ideal for constructions that require unsurpassed conductivity levels, chemical and permeation resistance and protection against static buildup.

Fluon ETFE LH-8000 exhibits advanced adhesive properties that allow it to bond to dissimilar materials, such as polyamides, polyethylenes and metals. Its adhesive functionality is ideal for producing multilayer structures in a one-step process without surface treatment, often eliminating the need for a tie layer. LH-8000 is used in the Sunbesta® two-layer fuel tube system, which provides excellent resistance to all fuels for long-lasting performance.

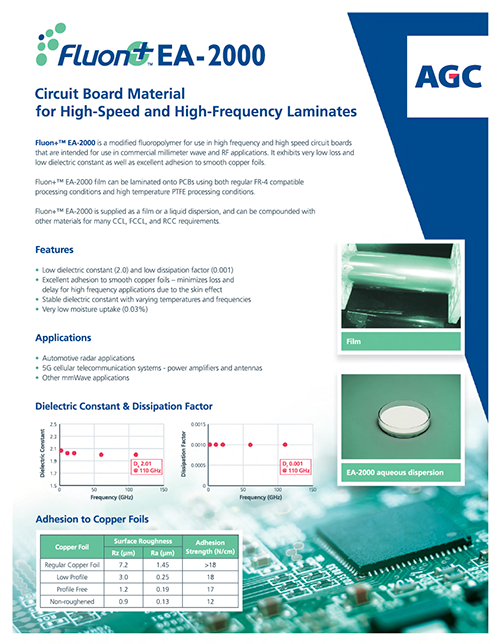

Fluon PFA EA-2000 perfluoro resin features a built-in functional adhesive group that enables one-step processing with other polymers and metals. This resin also eliminates the need for surface treatment or a separate adhesive layer.

- AH-600 series of products produce a lower melting compound that offers customers a more flexible process window, high temperature performance, excellent crack resistance and better compatibility with polyamide nylons for co-extrusion.

- AH-700 series of products provide a cost-effective solution with high performance that enable process temperatures for high-melt nylons.

- AH-800 series of products provide high temperature performance up to 200 °C and good stress crack resistance at elevated temperatures.

- LH-8000 has an ultra-low melting point of 180 °C-190 °C, which means that a fluoropolymer layer can be co-extruded with conventional engineering plastics like HDPE and PA in one processing step and does not require special equipment.

- EA-2000 resin is heat resistant to 260 °C and features superior chemical resistance, enhanced electrical characteristics, excellent non-stick properties, low frictional properties, water and oil repellency, a low dielectric constant and low dissipation factor.

Fluon ETFE AH

- Liquid and vapor fuel lines

- Compressor hoses

- Fuel tanks

- Filler necks

- Multilayer films and linings

- Electronic materials

- Coatings

Fluon LH-8000

- Chemical bags

- Hot water hoses

- Rubber hose mandrels

- Anti-stick conveyor belts

- Multilayer monofilament

- Interlayer insulation film for electronic substrates

- Tubes that convey harsh materials in the chemical, plastics, oil and gas, building and paint industries

Fluon EA-2000 PFA

- Printed circuit board coatings

- Interposers

- Steel plate laminates

- Heat-resistant insulating tape

- Heat-resistant laminated tubing

Click here to request an SDS sheet.

- Specific gravity

- Tensile strength & elongation

- CIELAB color analysis

- Pigment dispersion analysis

- TGA & DSC

- Optical microscope w/camera

- FT-IR

- Impact testing & hardness

- Melt flow indexer

- Conductivity/resistivity

- Capillary rheometer

Helpful Resources

Contact our fluoropolymer experts to discuss your specific needs.

Latest from the Blog

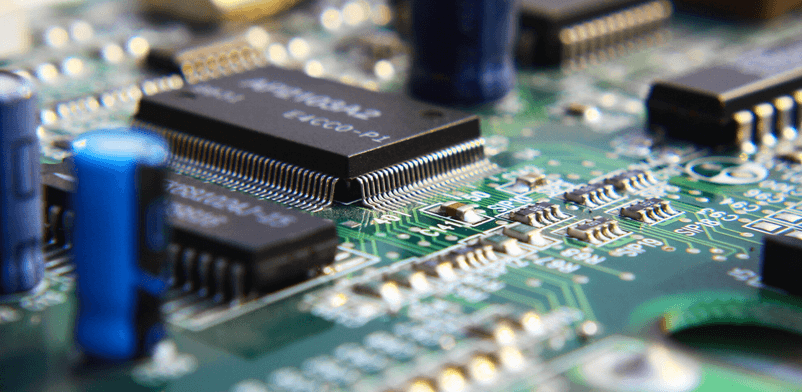

Fluon+™ PFA EA-2000 Adhesive Resins Serve as PCB Coatings to Speed Up Communication Rates in Autonomous Vehicles

By 2025, it is projected that the global market for partially autonomous and fully autonomous vehicles (AVs) will be $36 billion and $6 billion, respectively. These self-driving cars rely on sophisticated computer systems, sensors and other technology to safely navigate the road….

Read about this topic...Fluoropolymer Compounds Boost the Performance of Electric Vehicle Wiring

New fluoropolymer compounds for flat wire jackets enable automakers to move away from traditional rounded wires and reach 96 percent occupancy. Electric vehicle manufacturers are persistently working to develop ways to improve engine performance, raise output density, increase motor efficiency…

Read about this topic...Fluon+ EA-2000 Resin Meets Strict Demands of High-Frequency Printed Circuit Boards for 5G Technology

The new 5G cellular network is expected to become widely used by 2020. With already over 200 operators in more than 80 countries, 5G isn’t just on its way; it’s here. As a result, developers across the globe are working…

Read about this topic...