-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

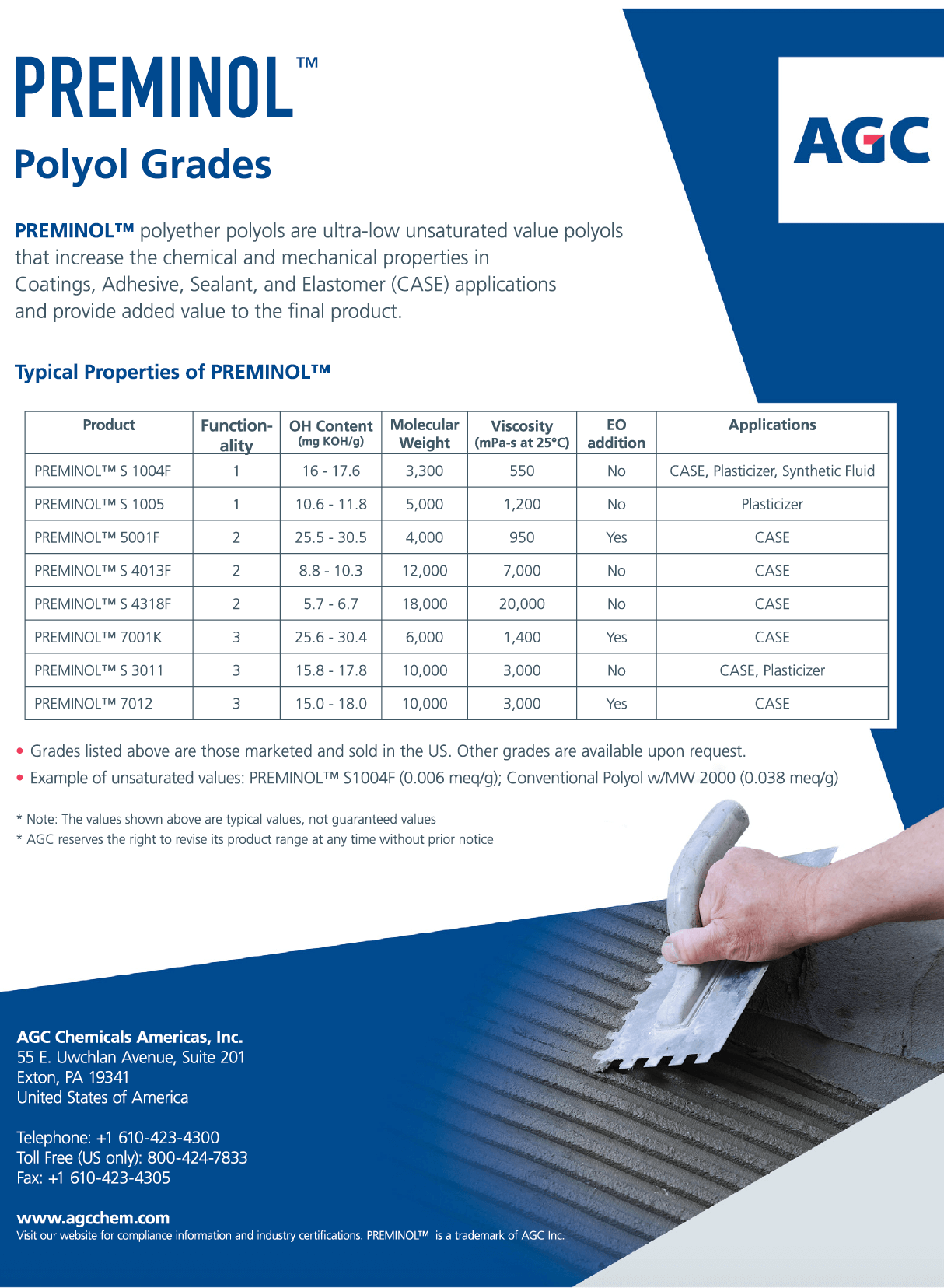

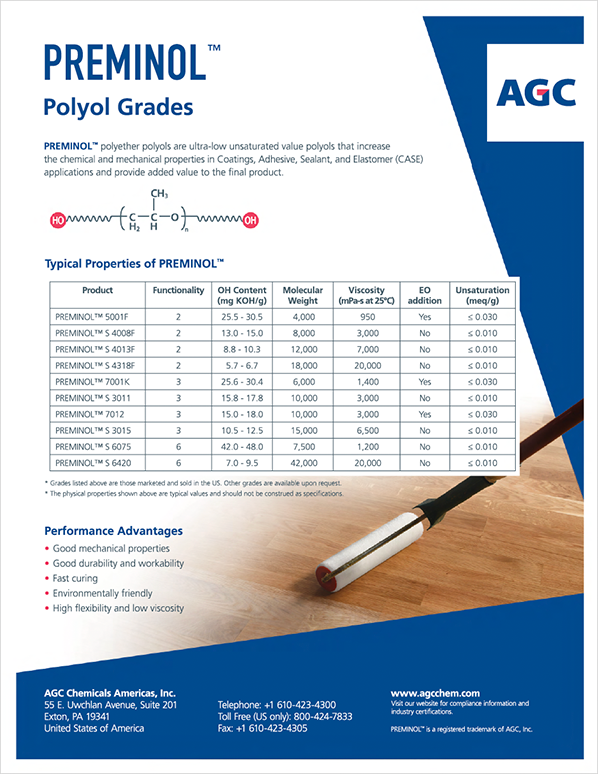

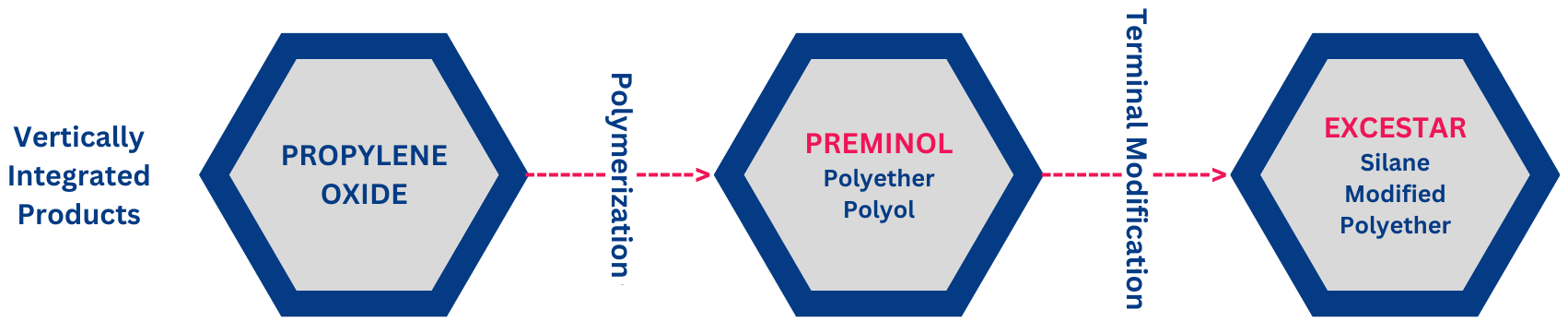

PREMINOL™ High Mw and EXCESTAR™ STP Polyols for CASE

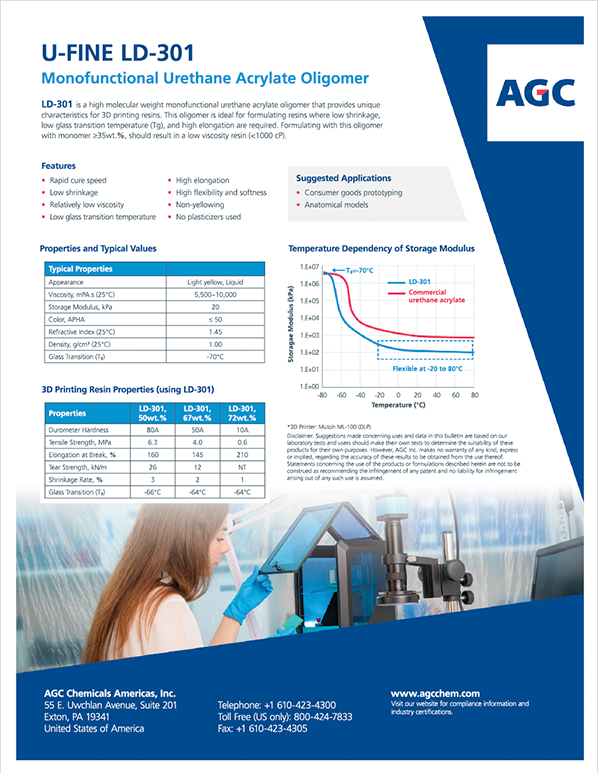

Monofunctional and Urethane Acrylates for OCA and 3D Printing

Polymers with narrow molecular weight distributions ranging from 4,000-42,000.

Multi-functional polymer for Silane Terminated Polyether (STP) applications

Silane Modified Polyether for CASE applications

![U-FINE LD-301-CMYK[1]](https://www.agcchem.com/wp-content/uploads/2024/09/U-FINE-LD-301-CMYK1.png)

Monofunctional Urethane Acrylate

Polyether polyols are key components used in the production of polyurethanes. AGC employs an advanced catalyst process which results in polyols with ultra-low monol content, and a narrow molecular weight distribution. These polymers are available in the Americas.

A new class of raw material for Optically Clear Adhesive (OCA) and 3D printing resins.

Properties of Polyols

PREMINOL has ultra-low monol content, high molecular weight ranging from 4,000-42,000, and a narrow molecular weight distribution. This provides good mechanical properties, high flexibility, good durability and good workability for coatings, adhesives, sealants, and elastomer applications.

EXCESTAR moisture-curable STPs are available in both linear and branched polymer structures that have high elongation with low viscosity used in construction sealants and elastic adhesives.

U-FINE LD-301 for 3D printing resins is a high molecular weight monofunctional urethane acrylate that provides low shrinkage, low glass transition temperature (Tg) and high elongation and can achieve a low viscosity resin.

(High Molecular Weight for Coatings, Adhesives, Sealants and Elastomers)

- Ultra-low monol content

- Good mechanical properties

- Fast curing

- High molecular weight

- High flexibility

- Good durability

- Narrow molecular weight distribution

- Good workability

(High Molecular Weight for Coatings, Adhesives, Sealants and Elastomers)

- Good mechanical properties - High flexibility and high cohesive force are suitable for elastic adhesive

- Good durability - High mechanical strength and high elongation enable to provide high durability sealants

- Good workability - Low viscosity of formulation enables to seal easily even at low temperatures

- Fast curing - enables to shorten the total process time

- Environmentally friendly (Plasticizer free, Solvent free) - High flexibility and low viscosity polymer enable to reduce the amount of plasticizer and solvent in the formulation

- Long-lasting elasticity, good weatherability and paintability, non-staining

- Home/Building/Construction

- Siding sealant (cement, composite board, sash)

- Reinforced concrete wall joint sealant

- Floor (wood, concrete) adhesive

- Decorative panel/Composite panel adhesive

- Roofing sealant

- Plasticizer for SMP formulations

- Floor coatings

- Industrial (Automotive/Transportation)

- Automotive interior and exterior adhesives

- Shipping container sealants

- Elevator assembly adhesive

- OEM and aftermarket coatings

- Electronics

- Electric component adhesive

- Optical Clear Resin/Optical Clear Adhesive

- Fiber optic coatings

- Synthesis of unique polymers and elastomers

Click here to request an SDS sheet.

- Acid value

- Density

- Unsaturation

- Viscosity

- Water content

View our Research and Development services.

Contact our experts to discuss your specific needs.

Latest from the Blog

Advantages of Fluorinated Solvents Over Aqueous Cleaning

For many industries like medical device, aerospace and automotive, parts and components be cleaned and degreased before they are assembled or shipped. While many cleaning solutions exist on the market, regulations for cleaning chemicals are becoming more stringent. The United…

Read about this topic...High-Purity Polyols Improve the Performance of Coatings, Sealants and Adhesives

Today’s builders and engineers rely heavily on polyurethanes. This popular plastic material is safe and versatile, making it ideal for many different end-uses. Polyurethane polymers are formed by the reaction of isocyanate and a polyol. However, because different polyols have…

Read about this topic...