-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

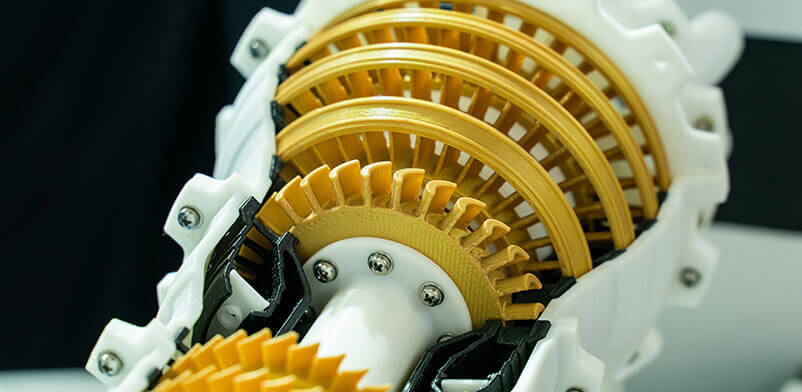

RESIFA™ SOLESPHERE™ Particles for 3D Printing/Additive Manufacturing

These microspherical silica particles can improve 3D printing resin formulations by adding tensile strength, flexural strength, dimensional stability and thermal resistance.

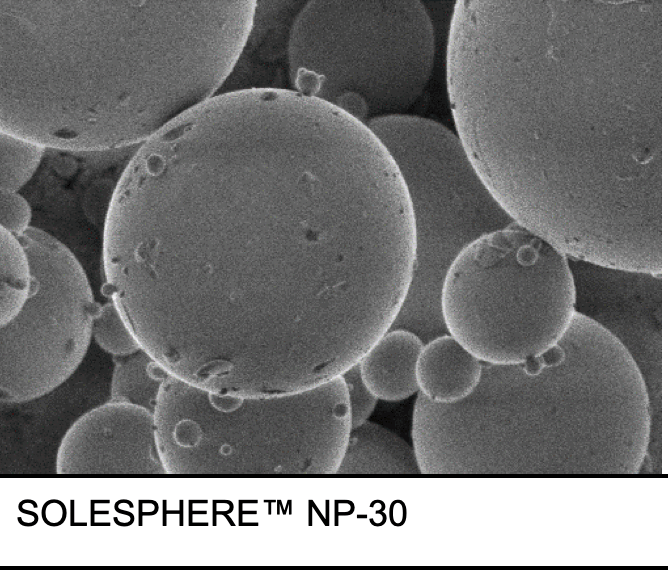

A family of microspherical silica with different particle sizes and porosities

RESIFA™ SOLESPHERE™ silica particles are very spherical, very pure and provide many functionalities for 3D printing resin formulations.

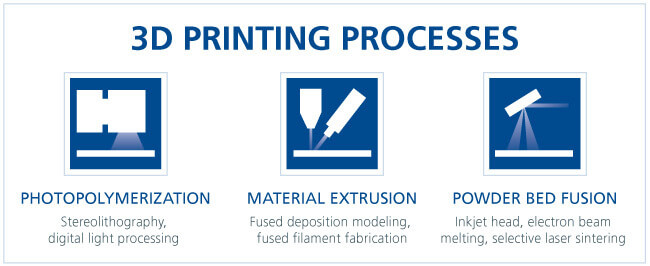

Additive manufacturing/3D printing is the process of creating solid three dimensional objects, layer by layer, with the use of computer design modeling. This process drastically reduces prototype costs and time to market. This field is rapidly growing and specialty fillers are needed to reach higher performance levels. SOLESPHERE microspheres can help improve product quality, increase performance properties and processing efficiencies for all three major 3D printing processes.

SOLESPHERE offers many benefits to various 3D printing resin formulations

- Higher tensile strength

- Increase stiffness/flexural strength

- Improved dimensional stability

- Easily dispersible in polymer matrix

- Thermal resistant/improved HDT

- Spacers (prevents blocking of soft polymer in powder fusion processes)

Silica loadings in 3D resin formulations can range from 3-50% by weight. Highly filled resin formulations present two major challenges: viscosity control and sedimentation. The physical properties of SOLESPHERE help mitigate these two major concerns.

Viscosity Control

Higher filler loadings typically mean higher viscosities, which decreases workability and processing speeds. However, the size and shape of SOLESPHERE microspherical silica reduce the viscosity. They are very spherical, have a really smooth surface and their particle size is larger than other silica offerings, providing lower surfaceareas. SOLESPHERE silica also form a matrix with typical 3D printing resins and other additives, keeping the constituents in suspension. This provides good viscosity stability over time.

Sedimentation (anti-settling)

Phase separation is when heavier additives settle downward during storage or idle time and lighter components migrate to the top. SOLESPHERE’s surface chemistry is very functional and provides a network within the polymer matrix. This matrix helps prevent phase separation during storage.

Markets

- Spherical, uniform porosity, narrow particle size

- Particle sizes: 3 - 20 μm

- Pore diameters up to 1000 Å

- Surface area: 30 - 800 m2/g

- Functional filler for 3D resin systems for VAT (SL, SLA, DLP)

- Increases tensile and flexural strength

- Improves dimensional stability

- Spacer for fusion jetting processes

Click here to request an SDS sheet.

Helpful Resources

Contact our silica experts to discuss your specific needs.

Latest from the Blog

SOLESPHERE Fine Silica Particles Enhance 3D Printing Resins Used in Different Processes

3D printing has completely transformed our world with its countless applications. It’s not just about rapid prototypes anymore. Now, we’re using it for everything from crafting prosthetics and medical gadgets to creating stylish clothes and educational tools. 3D printing resins…

Read about this topic...Research Shows Microsphere Silica Particles Improve Cosmetic and Skincare Product Formulations

Cosmetic and skincare formulations use a precise balance of ingredients to achieve the desired structure and performance of the final product. Formulators must understand the chemistry of each ingredient and how they will work together to develop products that deliver…

Read about this topic...5 Reasons why Silica Microspheres are Replacing Plastic Microbeads in Cosmetics and Skincare Formulations

Silica microspheres are a safer skincare ingredient than plastic beads, microplastics and nanomaterials. They are used for cosmetics and personal care products.

Read about this topic...