AGC Chemicals Americas

-

English

English

- Documentation

- Resources

- Blog

-

Customer & product inquiries: 1-800-424-7833

Customer & product inquiries: 1-800-424-7833

AGC Chemicals Americas

English

English

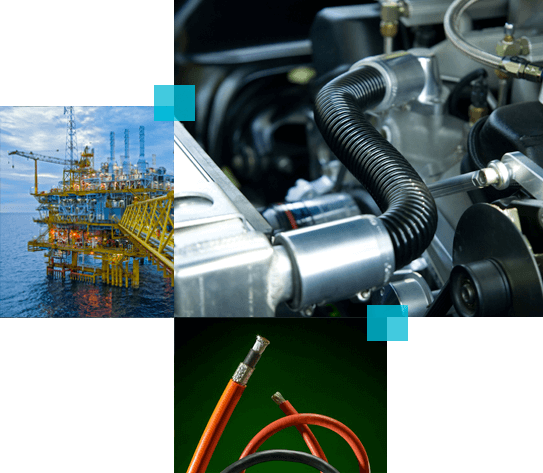

AFLAS® fluoroelastomers are the material of choice for parts and components that need to perform reliably in the world’s harshest environments. AGC formulated AFLAS resins from alternating polymers of tetrafluoroethylene and propylene to achieve unique properties over a conventional FKM-type fluoroelastomer. These properties include outstanding resistance to heat, chemicals, fuels, acids, bases, solvents, ozone and steam. Several AFLAS grades are approved by the Food and Drug Administration (FDA) for contact with food, making them an ideal material for parts like seals that are used in food processing applications where heat and/or aggressive chemicals will quickly degrade other types of rubber.

AFLAS 100 and 150 series fluoroelastomers are easily compounded by open mill and internal mixers. These polymer compounds are then fabricated into finished parts and shapes (like “rubber” seals and gaskets) using press molding, injection molding, extrusion and calendaring processes. AFLAS parts are used in many industries including:

AFLAS 200P specialty FKM maintains good base resistance and offers improved performance at cold temperatures. AFLAS PM-1100 and PM-3000 FFKM series fluoroelastomers are peroxide-curable and hold their performance at temperatures up to 270 degrees C.

Related Information