-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

Fluon+™ Melt Processable Compounds

Enhance properties and add pigment to a wide range of fluoropolymer resins including ECTFE, ETFE, FEP, PFA and PVDF.

Fluon+ Melt Processable Compounds are based on copolymer resins FEP, ETFE, PFA, PVDF and ECTFE.

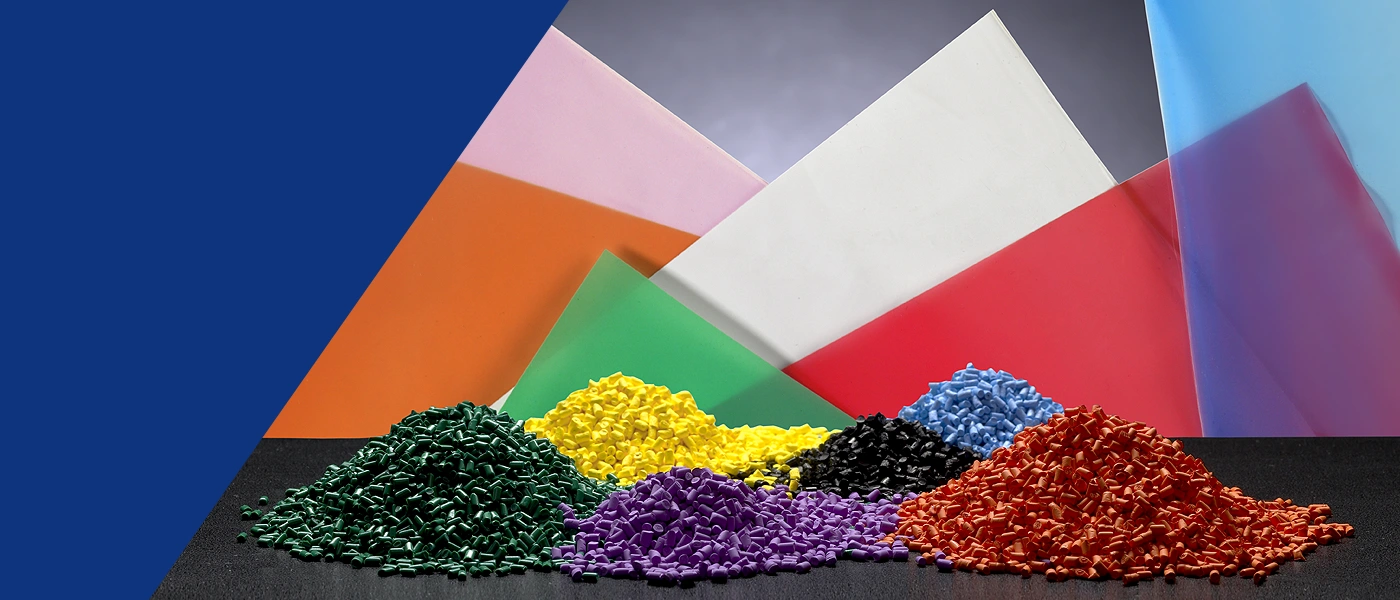

Fluon+™ Melt Processable Compounds are based on copolymer resins FEP, ETFE, PFA, PVDF and ECTFE. These fluoropolymer compounds extend the properties of chemical resistance, toughness and lubricity. The standard products are free of cadmium, hexavalent chromium and lead. All Fluon melt processable compound products are manufactured to precise specifications.

Types of Fluon+™ melt processable fluoropolymer compounds:

- Cross-linkable compounds

- Conductive/anti-static compounds

- Reinforced compounds

- Lubricated compounds

- Flexible compounds

- Adhesive compounds

- Color concentrates

- Foam concentrates

- Laser mark concentrates

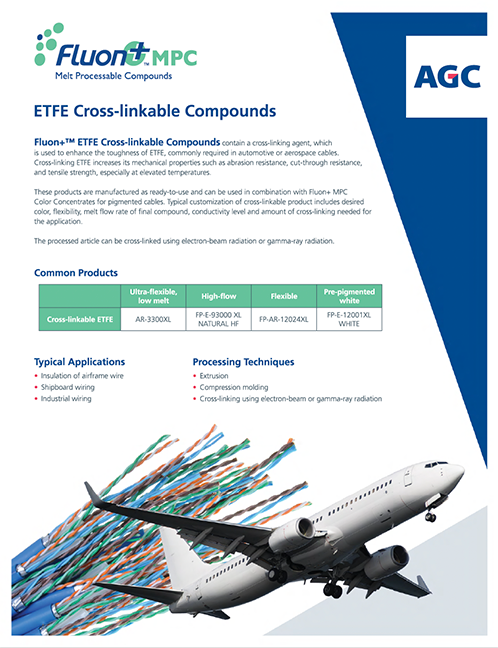

- Cross-linkable compounds: Increase mechanical properties such as scrape abrasion, cut-through resistance and tensile strength, especially at elevated temperatures.

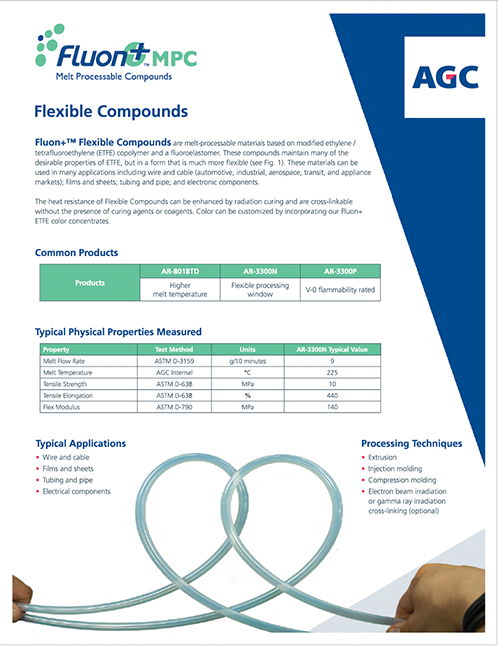

- Flexible compounds: Modified ETFE and a proprietary fluoroelastomer maintain many desirable properties of ETFE in a more flexible form. Heat resistance can be enhanced by radiation curing and can be cross-linked without the presence of curing agents or co-agents.

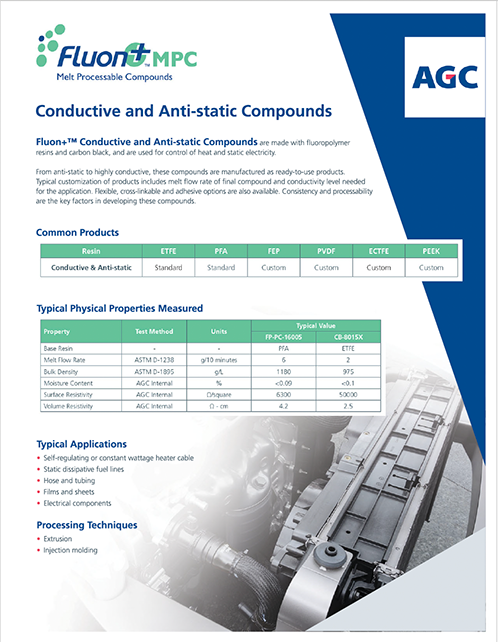

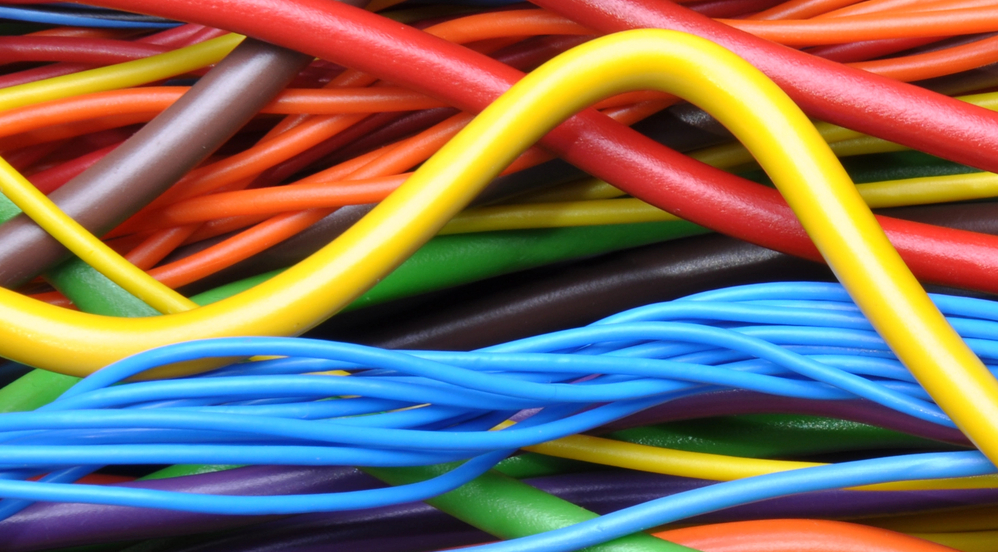

- Conductive/anti-static compounds: Control heat and static electricity. Wire coated with a conductive fluoropolymer may be used for freeze protection and process temperature control.

- Adhesive-grade compounds: Are modified ETFE used in applications requiring strong adhesion to polyamide polymers, especially nylon 12. These compounds also exhibit high permeation resistance to many fluids and gases, especially automotive fuels.

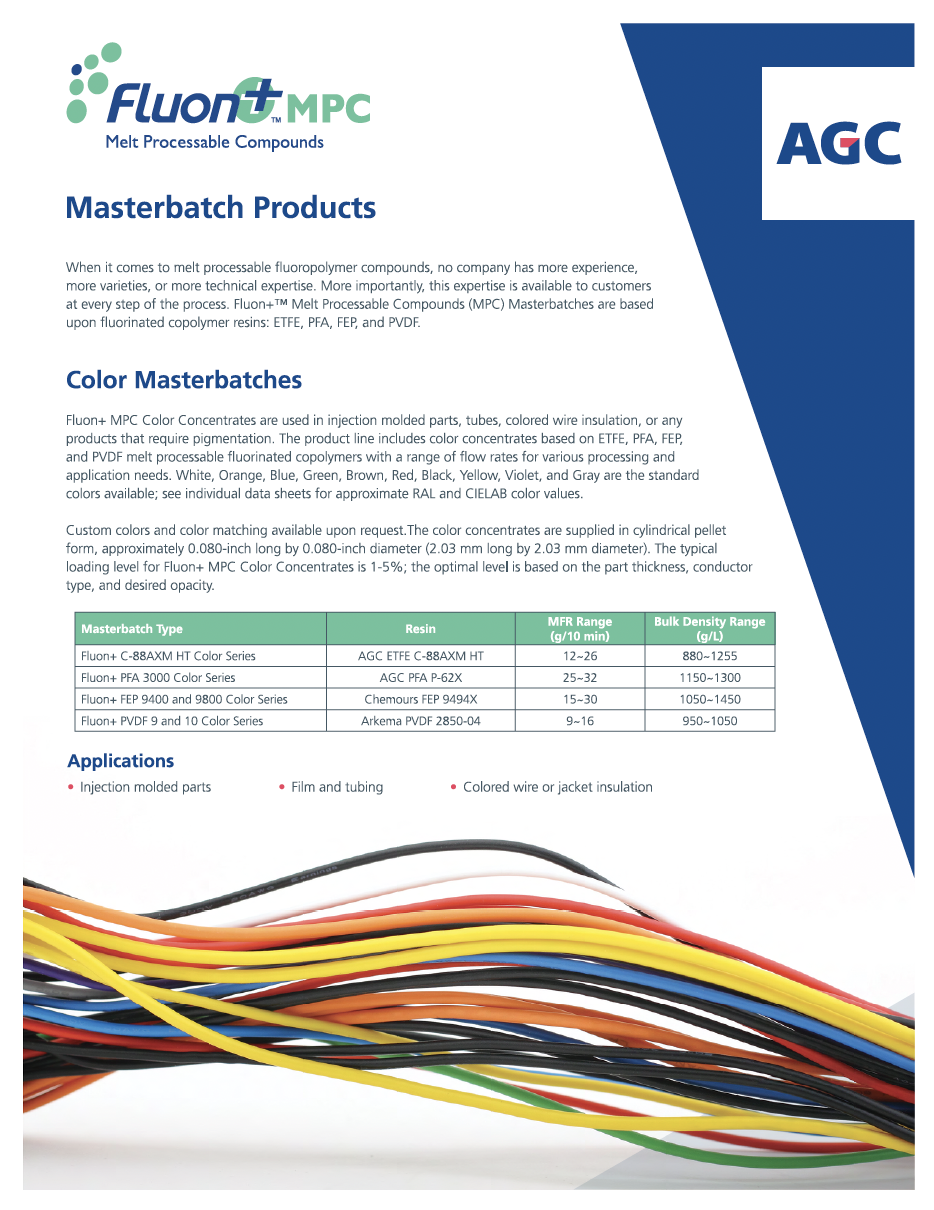

- Color concentrates: Superb surface finish, color consistency and dispersion even at high-speed extrusion rates.

- Reinforced compounds: Incorporate glass and mineral fillers for enhanced dimensional stability, abrasion resistance, shrinkage resistance and thermal conductivity characteristics.

- Foam concentrates: Designed for gas injection foaming used for manufacture of LAN and coaxial cables. The properties of a foamed insulation help minimize signal loss, enhance high-speed data transmission, and save weight and material.

- Lubricated compounds: Contain lubricious fillers such as PTFE and FEP. Used on car or truck brake “push-pull” cables where a low-friction, abrasion-resistant liner surface is needed.

- Laser mark concentrates: IR-MARK and UV-MARK additives are a series of concentrates designed for use in wire and cable applications that require permanent marking by infrared or UV laser. They can be incorporated into ETFE, PFA and FEP resins along with colorants.

- Color-coded wire insulation, tubing and molded parts (color concentrates)

- LAN and coaxial cables (foam concentrates)

- Wrap and thaw frozen pipes (conductives)

- Distillation column packings/sheets or other chemical processing industry applications (reinforced compounds)

- Car or truck brake cables (lubricated products)

- Wrap and thaw frozen pipes (conductive/anti-static compounds)

- Heat-shrinkable tubing for high-temperature and abrasive environments (cross-linkable products)

- Tapes and molded parts (powdered blends)

- Wire and cable jacket insulation where a laser-markable surface is required

Click here to request an SDS sheet.

- Specific gravity

- Tensile strength & elongation

- CIELAB color analysis

- Pigment dispersion analysis

- TGA & DSC

- Optical microscope w/camera

- FT-IR

- Impact testing & hardness

- Melt flow indexer

- Conductivity/resistivity

- Capillary rheometer

Helpful Resources

Contact our fluoropolymer experts to discuss your specific needs.

Latest from the Blog

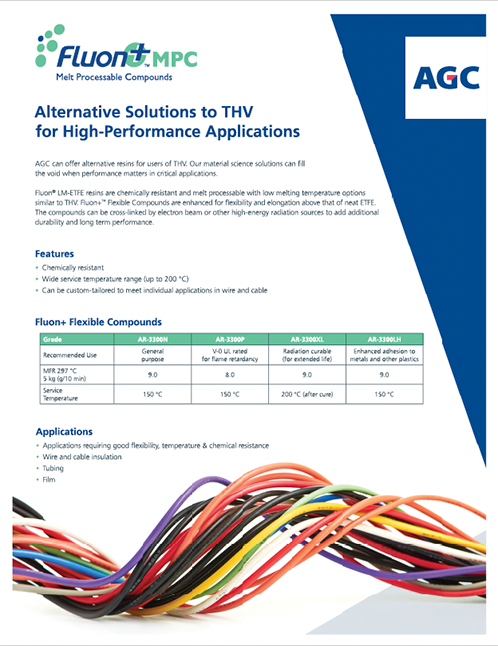

Consider these Fluoro Material Alternatives to THV for Wire and Cable Applications

Fluoro materials are available that can be used instead of THV in demanding applications. THV is already in short supply, leading to long lead times and higher prices.Now is the time to prepare for shortages in THV and find alternatives that match or exceed current application requirements.

Read about this topic...Fluoropolymer Compounds Boost the Performance of Electric Vehicle Wiring

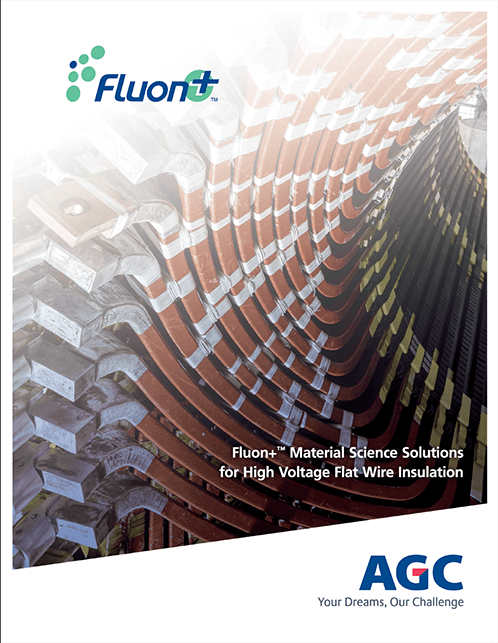

New fluoropolymer compounds for flat wire jackets enable automakers to move away from traditional rounded wires and reach 96 percent occupancy. Electric vehicle manufacturers are persistently working to develop ways to improve engine performance, raise output density, increase motor efficiency…

Read about this topic...AGC’s Commitment to Quality: Bringing Your Ideas to Life Through Specialized Testing Services

As a leading global supplier of fluorochemicals and materials, AGC is committed to upholding the highest quality standards across all of our product lines. But you need to consider more than just quality when selecting a product to add to…

Read about this topic...