-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

CYTOP™ Amorphous Fluoropolymers

Like PTFEs, but these fluoropolymers also exhibit high optical transparency and good solubility.

These amorphous fluoropolymer coatings are like transparent PTFEs.

Same excellent chemical, thermal, electrical and surface properties as conventional fluoropolymers like PTFEs, but also exhibit high optical transparency and good solubility in specific fluorinated solvents. CYTOP™ amorphous fluoropolymer coatings are like transparent PTFEs.

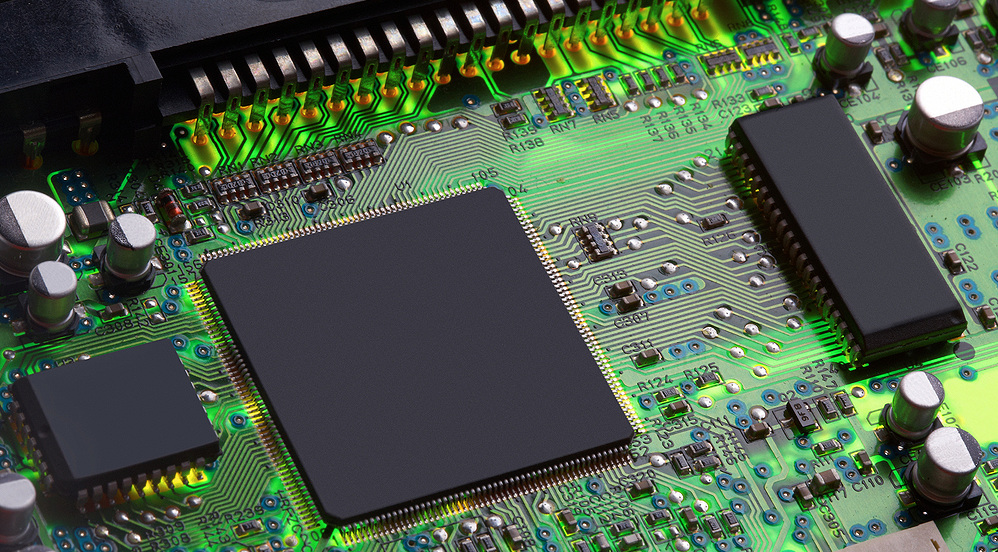

The thermoplastic characteristics of CYTOP, coupled with its transparency, solubility, insulation properties, resistance to chemicals, and oils/water repellency, make it a popular choice for coating electronic materials. CYTOP amorphous fluoropolymer coatings exhibit low refractive index, low coefficient of optical dispersion and good lamination properties. CYTOP amorphous fluoropolymers are available on request in various solvents (110ºC – 180ºC) and at various concentrations.

Markets

- Transparency

- Mold release

- Electric insulation

- Water and oil repellency

- Chemical resistance

- Moisture-proof

- Low refractive index

- Low coefficient of optical dispersion

- Good lamination properties

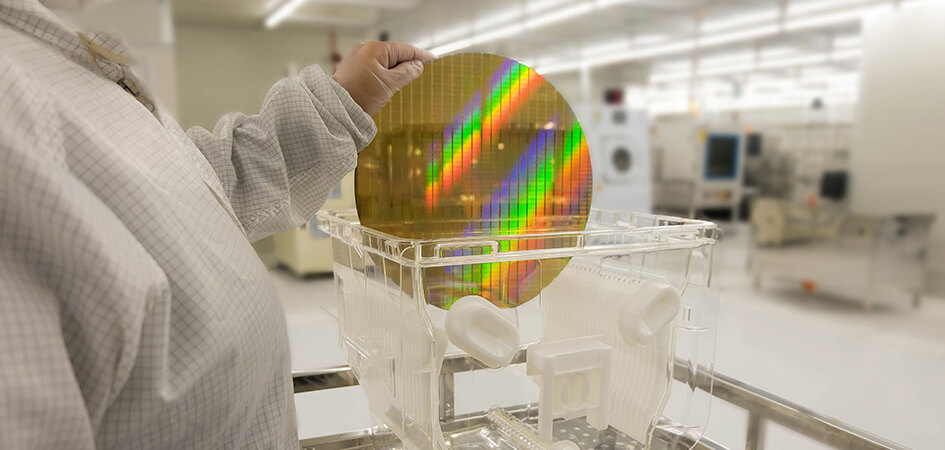

- Inter-level dielectric layer for semiconductors

- Pelicles

- Non-autofluorescence hydrophobic coating of microfluidics

- Hydrophobic coating of Electrowetting devices

-Hydrophobic coatings for BioChips

-Electrowetting for displays

- Antifouling coatings for photomasks

- Optical film

- Anti-reflective coatings

- Graded-index optical fibers

Click here to request an SDS sheet.

Characteristics

- High Transmittance: DUV 200 nm – NIR 2.0 µm > 95%

- Low Refractive Index, Minimal Color Observation: nD: 1.34, Abbe #: 90

- Electrical Properties: Dielectric constant: 2.1, volume resistivity > 1017 Ω·m

- Thin Film Coating: Soluble in perfluoro solvent: film thickness beyond 0.1 µm

Fluoropolymer Category

| Fluoropolymer | Perfluoropolymer | ||

|---|---|---|---|

| Crystalline | ETFE PVDF PVF ECTFE |

PTFE PFA FEP |

|

| Amorphous | Resins | LUMIFLON1 | CYTOP1 |

| Rubber | AFLAS1 Viton2 Fluorel3 |

Kalrez2 | |

1Registered trademark of Asahi Glass.

2Registered trademark of DuPont.

3Registered trademark of 3M.

Optical Properties

| CYTOP | PTFE | PFA | PMMA | Remarks | |

|---|---|---|---|---|---|

| Refractive Index | 1.34 | 1.35 | 1.35 | 1.49 | Abbe Refractormeter |

| Transmittance (%) | 95 | opaque | opaque | 93 | Visible Region, 200 µm |

| Abbe Number | 90 | -- | -- | 55 | Abbe Refractometor |

Physical Properties

| CYTOP | PTFE | PFA | PMMA | Remarks | |

|---|---|---|---|---|---|

| Glass Transition Temperature (°C) | 108 | (130) | (75) | 105-120 | DSC |

| Melting Point (°C) | not observed | 327 | 310 | iso 160 syn 200 |

DSC |

| Density (g/cm3) | 2.03 | 2.14-2.20 | 2.12-2.17 | 1.19-1.20 | 25 °C |

| Contact Angle of Water (degree) | 110 | 114 | 115 | 80 | 25 °C |

| Critical Surface Tension (dyn/cm) | 19 | 18 | 18 | 39 | 25 °C |

| Water Absorptivity (%) | <0.01 | <0.01 | <0.01 | 0.3 | 60 °C in water |

| Durometer Hardness | HDD78 | HDD55 | HDD58-60 | HDD92 | ASTM D2240 |

| Linear Expansion Coefficient (cm/cm/°C) |

7.4*10-5 | 1.0*10-4 | 1.3*10-4 | 8.0*10-5 | TMA (40-100 °C) |

Contents

| Gas Permeation | Comparison of Oxygen | ||

|---|---|---|---|

| Gas | Permeability (cm3 cm/cm2s Pa) | Product | Oxygen Permeation (cm3 cm/cm2s Pa) |

| He | 8.9*10-12 | CYTOP | 4.2*10-13 |

| O2 | 4.2*10-13 | PTFE | 3.2*10-13 |

| N2 | 1.0*10-13 | PE | 2.2*10-13 |

| Saran | 4.0*10-16 | ||

| Moisture Permeation | |

|---|---|

| Product | Permeability (cm3 cm/cm2s Pa) |

| CYTOP | 1.1*10-12 |

| PI | 4.3*10-11 |

| Silicon Rubber | 3.2*10-9 |

| HDPE | 9.0*10-13 |

| Saran | 7.0*10-13 |

Chemical Resistance

| Chemicals | Weight Change (%) | Appearance | Remarks |

|---|---|---|---|

| Acids 12N HCl 99% H2SO4 50% HF |

0.0 | No change | 60 °C*1 week 60 °C*1 week R.T.*1 week |

| Alkalis 10% NaOH 44% NaOH |

0.0 | No change | 60 °C*1 week |

| Organic Solvents Hexane Benzene Acetone Methylethylketone Trichloro Ethylene Carbon Tetrachloride |

0.0 | No change | R.T.*1 week |

How to read the "Grade"

CTX-809AP2 / CTL-109AE/CTL-809M

| CYTOP | Molecular Weight | Boiling Point of Solvent | Polymer Content (%) | Functional Group | Optional | |

|---|---|---|---|---|---|---|

| Brand | X: standard (250K to 300K) L: low (150K to 200K) |

1: 100 °C/100 series for dip coating 8: 180 °C/800 series for spin coating |

7% or 9% concentration of the solution | A: standard M: for adhesion to inorganic materials |

E, P, P2, none | |

| CT | X | 8 | 09 | A | P2 | |

| CT | L | 1 | 09 | A | E | |

| CT | L | 8 | 09 | M |

Major Types of CYTOP™

- Dip Coating: CTL-109AE

- Spin Coating: CTX-809A; CTX-809AP2; CTL-809M

How to use CYTOP™

- AGC normally supplies a 9% solution.

- To achieve the thickness desired, control the concentration of the CYTOP™ solution as well as speed of coating. For this purpose, we supply the solvent at the same time as the CYTOP™ solution.

Helpful Resources

Call our fluoropolymer experts to discuss your specific needs.

Latest from the Blog

New Office in Northern California

(AGCCA) has opened a new office in Cupertino, California, to support the advanced materials needs of semiconductor and electronics manufacturers located on the northern West Coast. The Business Development Office Chemicals (BDOC) will enable the company to build and enhance…

Read about this topic...Transparent Amorphous Fluoropolymer Coatings Protect Sensitive Electronics and Optics Components and Transmit Light

Components inside electronic devices can rust when exposed to contaminants and moisture. This corrosion can reduce performance and cause electrical shorts and device failure. Transparent fluoropolymer coatings offer the insulation properties of standard PTFEs to protect sensitive components while providing…

Read about this topic...Fluon+ EA-2000 Resin Meets Strict Demands of High-Frequency Printed Circuit Boards for 5G Technology

The new 5G cellular network is expected to become widely used by 2020. With already over 200 operators in more than 80 countries, 5G isn’t just on its way; it’s here. As a result, developers across the globe are working…

Read about this topic...