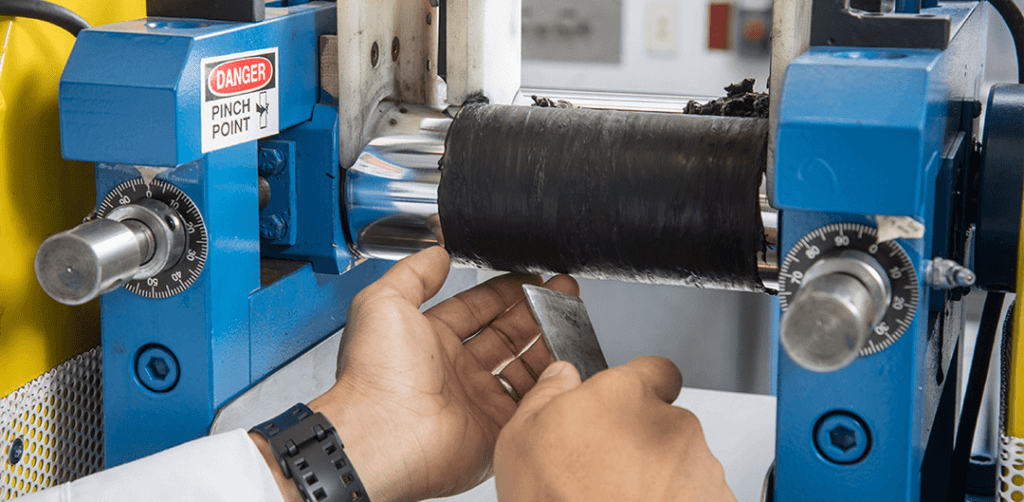

Sep 14, 2017 | Fluoroelastomers

We recently enhanced our AFLAS® fluoroelastomer testing lab in Exton, Pa. with new equipment for fluoropolymer testing. It’s important that we have the latest equipment so we can support our customers’ product development. AFLAS resins are used in so many industries now, that constant R&D is needed to develop new products for specific applications. New…

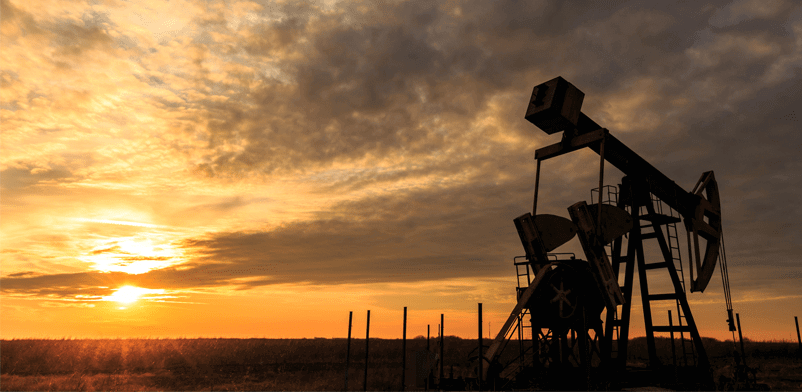

Apr 17, 2018 | Fluoroelastomers

To extract as much product out of an oil or gas reservoir as possible, exploration and production companies use enhanced oil recovery (EOR) techniques to operate in high-pressure, high-temperature (HPHT) downhole conditions. These production methods typically utilize gas, steam or chemical injection to extend the productive life of a reservoir. Although EOR techniques are extremely…

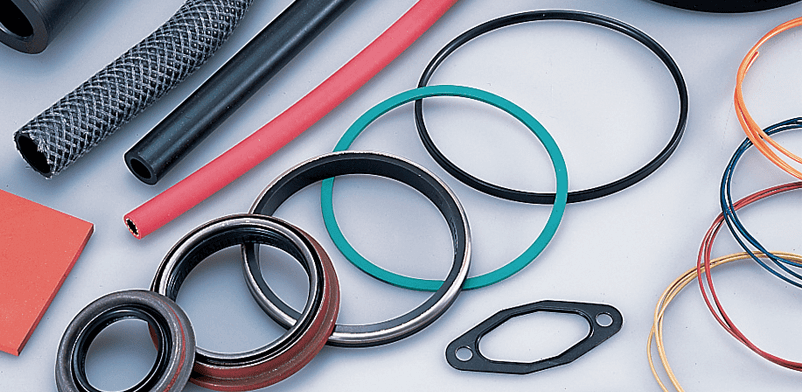

Jul 17, 2018 | Fluoroelastomers

Productivity and safety in oil and gas recovery operations depend on the strength of equipment, parts and systems. Downtime or injuries from equipment failure are unacceptable, so machinery must be built with parts and components that will not fail in these harsh environments. Hardworking oilfield equipment parts include durable packers, bladders, seals, gaskets and O-rings….

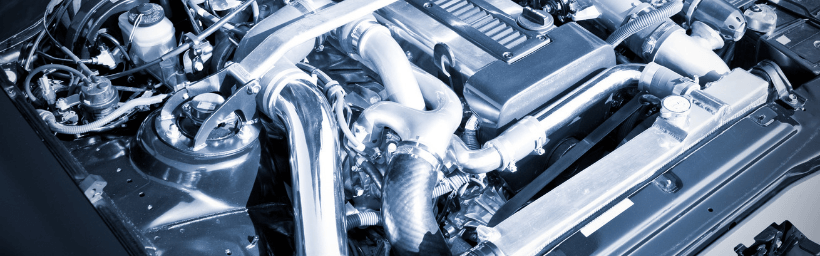

Aug 23, 2018 | Fluoroelastomers, Automotive products

FKM is the ASTM designation for a class of fluorinated, carbon-based synthetic rubber, commonly known as fluoroelastomers, which were introduced in the 1950s. FKMs exhibit impressive heat resistance as well as resistance to high pressures, chemicals and other fuels. These performance qualities made them an ideal material for high-performance seals, O-rings and gaskets used in…

Apr 29, 2019 | Fluoroelastomers, Automotive products

Today’s automotive engineers are challenged to design lightweight vehicles that operate with maximum power and minimal fuel consumption. With great emphasis placed on turbo efficiency, it is important to select materials for engine components that can stand up to demanding, under-the-hood applications. Recent advances in lamination technology for multi-layer hose constructions have caused manufacturers to…

English

English