-

AGC Chemicals Americas

Choose Your Region

-

English

English

- Customer & product inquiries: 1-800-424-7833

Fluon® ETFE Resins

Provides superior physical toughness to meet a wide range of product applications.

Melt-processable copolymers composed of ethylene and tetrafluoroethylene

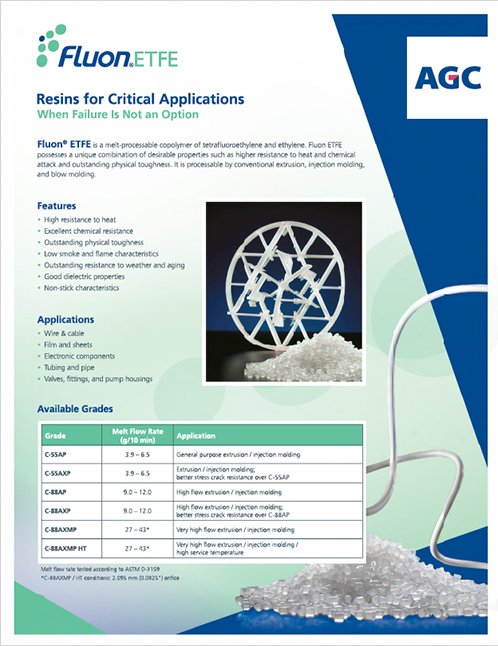

Fluon® ETFE resins are melt-processable copolymers composed of ethylene and tetrafluoroethylene (ETFE). Their superior physical toughness and resistance to chemicals, UV and extreme temperatures make these resins ideally suited for a wide range of high performance products and components such as industrial wiring and electronics.

Fluon® ETFE Resins

ETFE resins are also resistant to ultraviolet light, so they are ideal for outdoor use. A 16,000-hour accelerated weathering test (comparable to 30 years’ exposure) produced almost no signs of film deterioration.

ETFE resins are available in pellet or powder form for processing using the following methods:

- Extrusion molding

- Injection molding

- Blow molding

- Electrostatic coating

- Rotolining

- Rotomolding

ETFE resin compounds are also available in a variety of color masterbatch concentrates, custom reinforcements or conductivity levels.

Fluon® LM-ETFE Resins

Fluon® LM-ETFE resins are modified to provide a 30 °C to 40 °C lower melting point than conventional ETFE resins. The wider temperature range allows for improved processability, flexibility and strength.

These low melting fluoropolymer resins are processable by conventional extrusion and injection molding techniques. They are also available in rotomolding, rotolining and adhesive grades.

Sunbesta® and Sunbesta ZV Fuel Hose Constructions Product Data Sheet

ETFE Resins:

- Continuous use temperature range from -200 to 200 °C

- Resistant to low-temperature impact down to -80 °C

- Superior tensile elongation and strength

- Can be cross-linked with electron beam for increased toughness

- Stable mechanical and electrical properties

- UV resistance

- Long-term weatherability

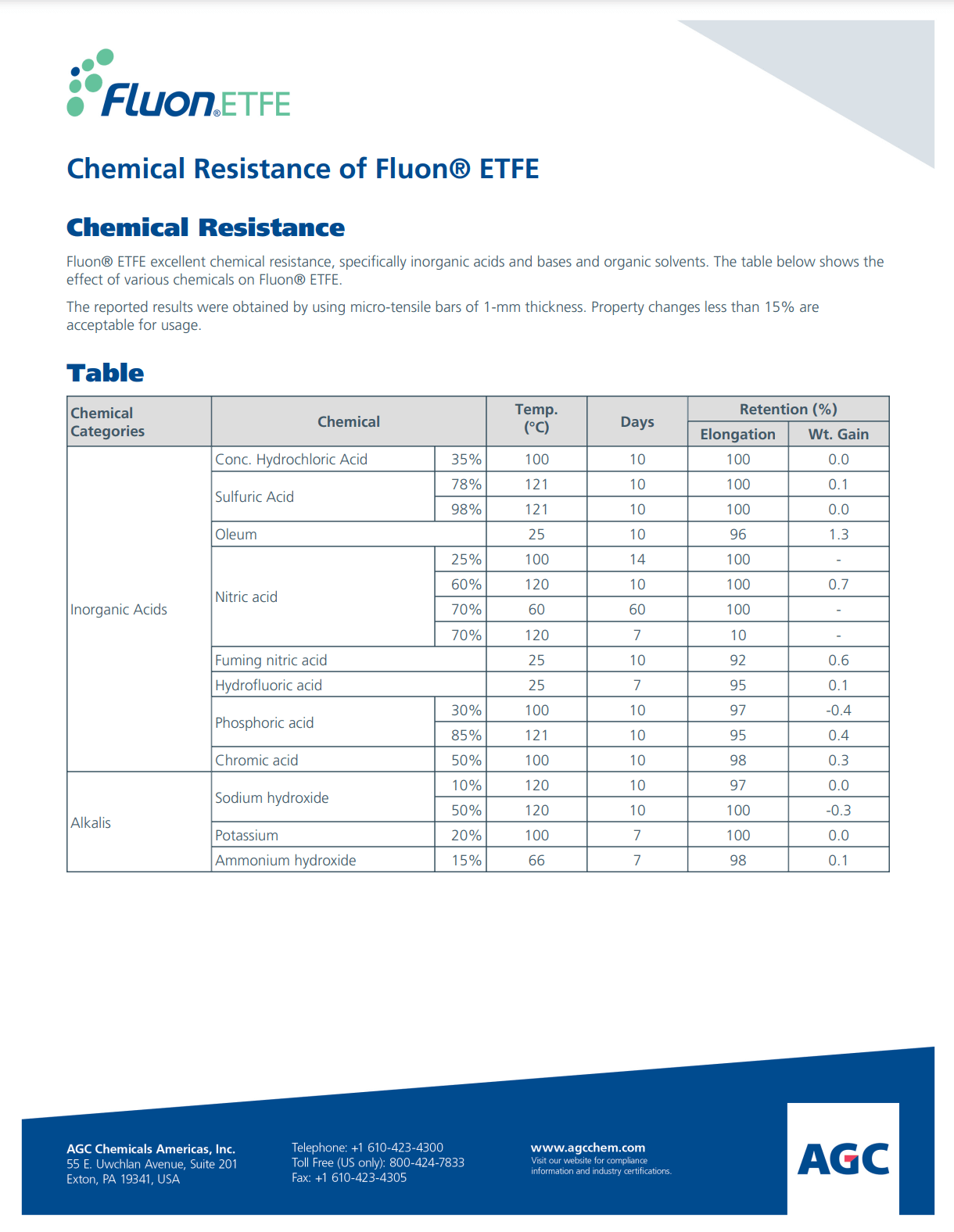

- Excellent chemical resistance to inorganic acids/bases and organic solvents

- Nonflammable material conforming to UL Standard 94V-0

- FDA-compliant for Food Contact Notification (FCN) number 481

LM-ETFE Resins:

- High heat resistance

- 30 °C to 40 °C lower melting point than other ETFE materials

- Outstanding resistance to weather and aging

- Nonflammable material conforming to UL Standard 94V-0

- Dielectric properties

- Non-stick characteristics

- Improved optical clarity; higher transparency than conventional EFTE

- Higher limiting oxygen index (40% versus 31%)

- Low smoke and flame characteristics

- Can withstand flex of over 100,000 times

- Can be cross-linked with electron beam for increased toughness

- FDA-compliant for Food Contact Notification (FCN) number 481

- Food industry

- Wire and cable coating

- Film and sheets

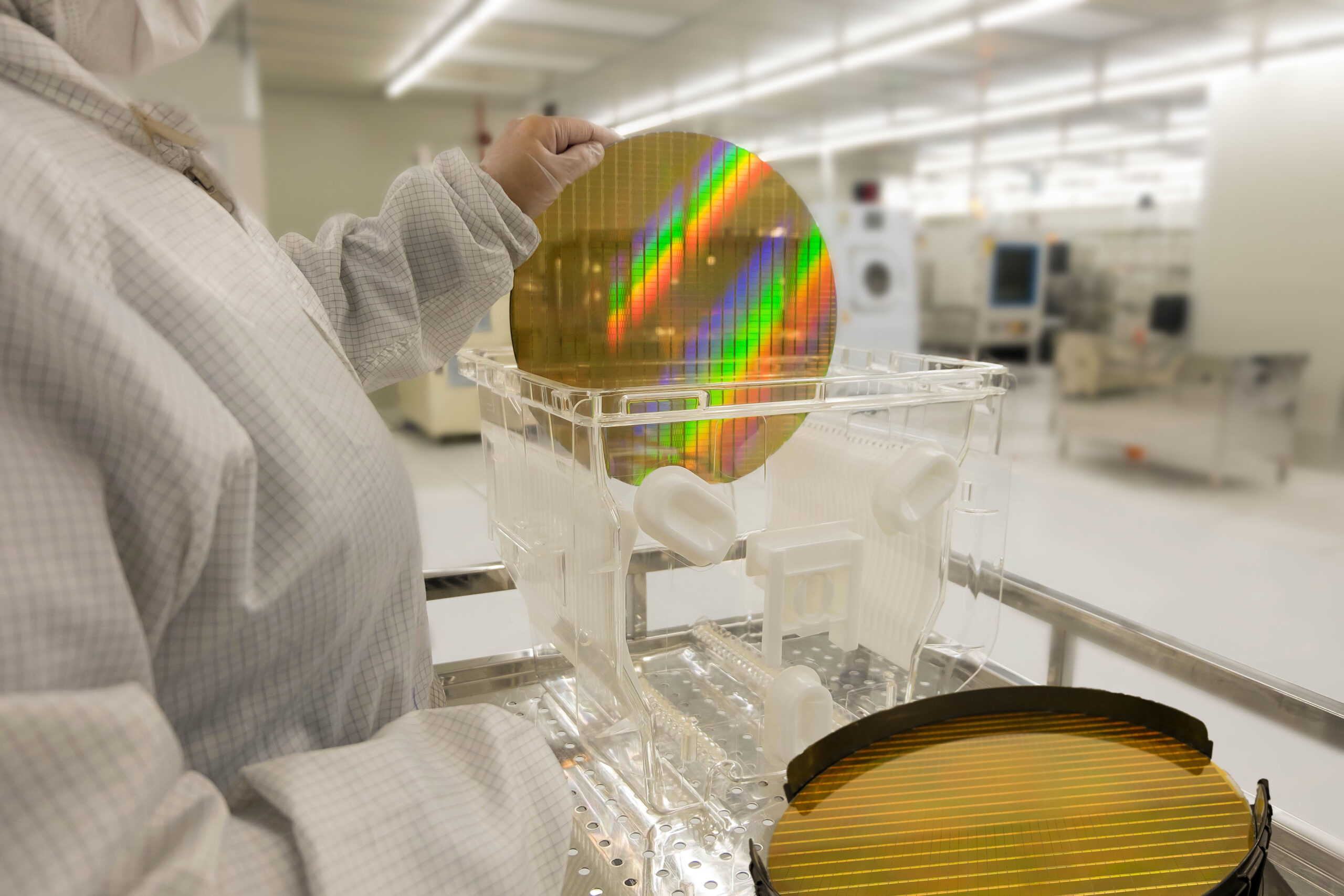

- Semiconductor and electronic components

- Tubing and pipe

- Valves, fittings and pump housings

- Electrostatic and rotolined vessel linings

- Fuel hoses

Click here to request an SDS sheet.

- Physical testing

- Anaytical testing

- Environmental studies

- Material identification

- Thermal analysis

- Rheometry

- Microscopy

Helpful Resources

Fluoropolymers FAQs

A: Coatings made with fluoropolymer resins are ultra-weatherable and maintain their excellent appearance on buildings, bridges and other structures, as well as on aircraft, automobiles and solar panels. They can protect steel, aluminum and concrete from degradation by UV light, wind and rain, and corrosion. AGC’s LUMIFLON® FEVE resins are transparent fluoropolymer resins that can be used to make both clear and pigmented coatings that offer substantial life cycle cost savings over conventional coatings.

A: ETFE and PFAs can be compounded to provide adhesive properties that are compatible with many different materials including polyethylenes, metals and polyamide polymers like nylon 12. Though they adhere to the base materials, they resist permeation from harsh fluids and gasses. This makes them attractive for automotive parts and components. For example, there are fluoro-based adhesives that can chemically adhere to dissimilar materials, reduce weight and eliminate tie layers in multilayer hose constructions. They are ideal for constructions that require unsurpassed conductivity levels, chemical and permeation resistance, and protection against static buildup. Some perfluoro resins can even eliminate the need for surface treatment or a separate adhesive layer.

A: Fluorinated cleaning solvents (also called fluorosolvents) are generally used to clean high-value electronics and critical metal components used in the medical device, automotive and aerospace industries. They have a higher unit price than aqueous cleaning, n-propyl bromide and chlorinated solvents, but often have reduced long-term costs and associated risks. Compared with aqueous cleaners, fluorosolvents have lower surface tension, provide superior cleaning power, and are better able to get into tight spaces. Compared with nPB and chlorinated solvents, fluorosolvents have no pungent smell, are nontoxic and nonflammable, are more environmentally friendly and are more compatible with plastics.

A: Yes. Films made from fluoropolymers (called ETFE films) are used around the world in architectural projects and greenhouses because they are safer and lighter than glass. ETFE film requires less structural support, which reduces building time and costs. The material is heat resistant, chemical resistant and fire resistant with excellent thermal insulation properties, high light transmission and long-term weatherability. Its high level of heat retention, combined with its ability to allow in more natural light than glass, can reduce energy costs by up to 30% compared to glass. Despite being lighter than glass, ETFE film will not easily rip or scratch over time, even in the harshest environments. The film has a high tensile elongation (200 – 510%) and tear strength, as well as a thermal melting point of 260 °C and a linear thermal expansion coefficient of 9.4. Click here to see a comparison of ETFE film versus architectural glass.

A: Yes. Films made from fluoropolymers (called ETFE films) are used for architectural fabrics for tensile membrane structures like roofs, awnings, wraps and facades. Some of today’s most exciting building designs include colorful and translucent textile skins. They not only increase the beauty and function of buildings, but provide UV and visible light transmission, insulation properties, durability and weather resistance. Click here to see a comparison of ETFE film versus other architectural fabrics.

Call our fluoropolymer experts to discuss your specific needs.

Latest from the Blog

Consider these Fluoro Material Alternatives to THV for Wire and Cable Applications

Fluoro materials are available that can be used instead of THV in demanding applications. THV is already in short supply, leading to long lead times and higher prices.Now is the time to prepare for shortages in THV and find alternatives that match or exceed current application requirements.

Read about this topic...Celebrating Fluon® ETFE’s 50th Anniversary

Created in 1972 by AGC, Fluon® ETFE high-performance fluoropolymer resins have been used in hundreds of different applications worldwide including tubing, piping, wire/cable coatings, hoses, architectural films, valves and other components. When made with ETFE melt-processable resins or films, these…

Read about this topic...Protect Life-Saving Pharmaceuticals with Fluorinated Resin Coatings for Glass Packaging

The COVID-19 pandemic brought public attention to the complex pharmaceutical supply chain—product development, production and distribution. Playing an important role in the worldwide vaccination effort are the glass vials that contain the billions of doses needed for global distribution. To…

Read about this topic...