-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

The FDA restricts the loading levels of organic and inorganic UV actives in sunscreen formulations. This can make it difficult for formulators to achieve an SPF 15 rating or higher and claim broad spectrum effectiveness. However, adding 1-2.5% SOLESPHERE silica to sunscreen formulations makes it possible to:

- Boost SPF to the required level

- Reduce UV actives while still meeting the desired SPF rating

- Improve the spreadability of inorganic formulations that use titanium dioxide and/or zinc oxide

- Make inorganic formulations incorporate better into the skin

- Reduce the white appearance of inorganic formulations

- Reduce the UV actives in formulations to reduce skin irritation and promote skin tolerance

- Resistant to highly reactive organic and inorganic chemicals

- Excellent volume resistivity (greater than 1016Ω cm)

- Radiation resistance up to 200 MRad of gamma-ray radiation

- Unaffected by extended exposure to 200 °C steam

- Continuous use at 230 °C

- Resistant to highly reactive organic and inorganic chemicals

- FDA-compliant for food contact

- Organic and inorganic UV actives

- O/W, W/O and anhydrous formulations

- Creams and lotions

- Lip balms and lipsticks

- Sun protection sprays

- Daily wear cosmetic foundations

Click "Formulations" tab on the left to see the following test formulations using SOLESPHERE H-33 and H-53 grades:

- Shade Perfect - ACTS 22514

- Coconut Luxe Ultimate Sun Defense ZnO Sunscreen - ACTS 22883

- Coconut Care SPF ACTS 22781 and SPF+ - ACTS 23095

- Hydrating Silk Sunscreen - ACTS 23036

- Hydrating Glow Serum - ACTS 22495

- Fresh Coat Organic Sunscreen - ACTS 22343

- Fun in the SUNflower SPF - ACTS 22821

- All Good Sunscreen - ACTS 22869

- Aqueous Sun Runner - ACTS 22839

- Ultra-Radiating Sunscreen ACTS 23044

Click here to request an SDS sheet.

Particle surface observation by Scanning Electron Microscope

Particle strength

Particle strength| Grade | NP-30 | H-51 | H-52 | H-53 |

|---|---|---|---|---|

| Pore volume (mL/g) | 0.02 | 0.8 | 1.6 | 2.0 |

| Compression strength (MPa) | 1900 | 40 | 4 | 3 |

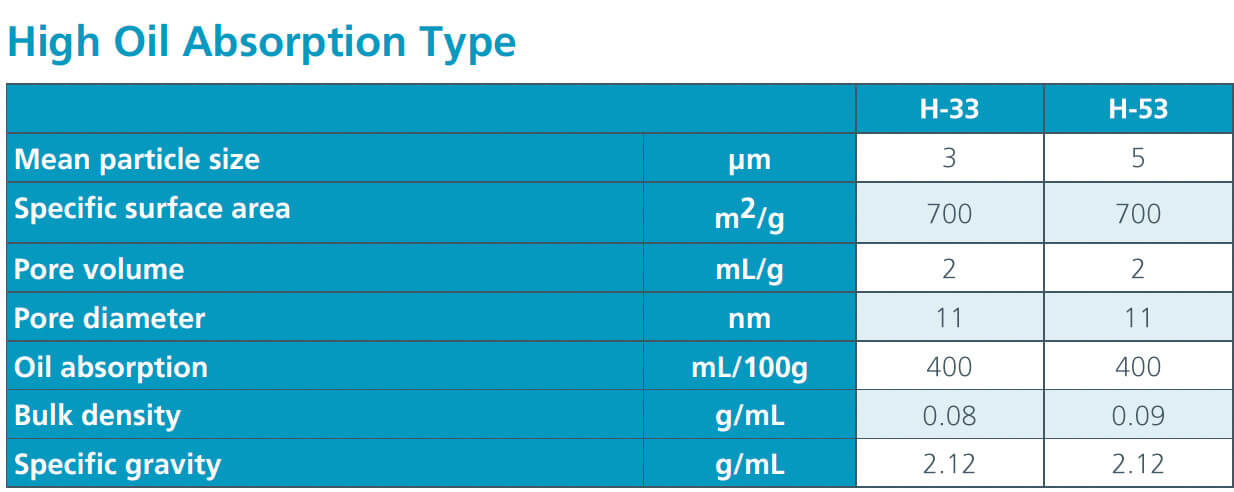

Oil Absorption and Particle Diameter

Moisture retention capability test

Moisture absorption is affected by specific surface area and pore volume.

Texture feeling test

Test method: Applied 0.5mg/cm test powder to artificial leather Supplare (made by Idemitsu Techno Fine),

and evaluated texture by KES-SE friction tester (made by Kato tech and sensor: artifical leather Supplare, load 25g).

Soft Focus Effect

Test method: Applied SOLESPHERE samples to the surface of Supplare, and then monitored with a digital microscope (x 25).

SOLESPHERE prevents oily skin and covers up wrinkles.

Optical diffusion (one characteristic of SOLESPHERE) gives these effects.

These effects are proportional to particle size and pore volume.

Contact our fluoropolymer experts to discuss your specific application.

Latest from the Blog

Tips for Selecting Moisture Repellents for Nonwoven Fabrics

Many products we use every day are made from nonwoven fabrics, including home furnishings, disposable medical products, and automotive parts and interiors. Nonwoven fabrics can be treated with moisture repellents as rolled goods. This makes them more durable, able to…

Read about this topic...Improve the Efficiency of Lithium Production and Recycling with Ion Exchange Membranes

Lithium is a critical raw material for clean energy technologies. It is used to produce lithium-ion batteries that power electric vehicles and energy storage systems. As more companies transition to clean energy, demand for lithium is projected to rise from…

Read about this topic...High-Purity AGC Fluoropolymers for Semiconductor Production

AGC fluoropolymers are valuable for modern semiconductor manufacturing. Known for their exceptional chemical resistance and high purity, these materials are used to mold, insulate and protect critical components exposed to demanding conditions during chip production. As fabrication processes grow more…

Read about this topic...