Reading Time: 3 minutes

Electric vehicles use high-voltage cables to transmit electrical power to the charging port, battery, engine and other internal components. The automotive industry requires these cables to be lightweight to improve vehicle efficiency and all-electric range.

These engines are very hot and contain harsh chemicals. An advanced insulation material is needed to protect cables from this abrasive environment as well as high-voltage stress. The ideal material choice is cable insulation that minimizes bulk and weight.

AFLAS® Fluoroelastomers Produce Lighter Cables

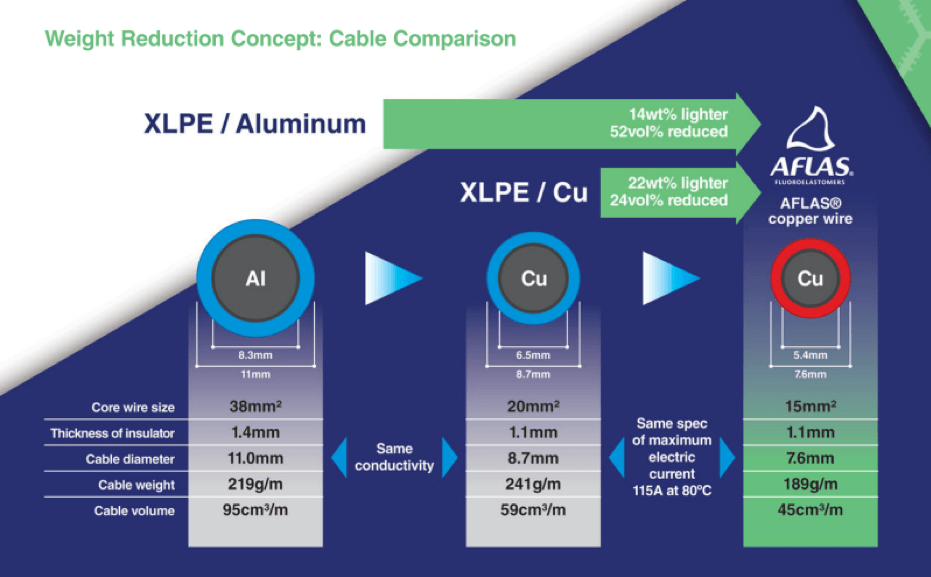

AFLAS® fluoroelastomers offer a lighter, thinner and more flexible insulating material for high-voltage cables than XLPE wire. Less material is required to achieve insulating properties, so the wire size is smaller than XLPE/aluminum and copper.

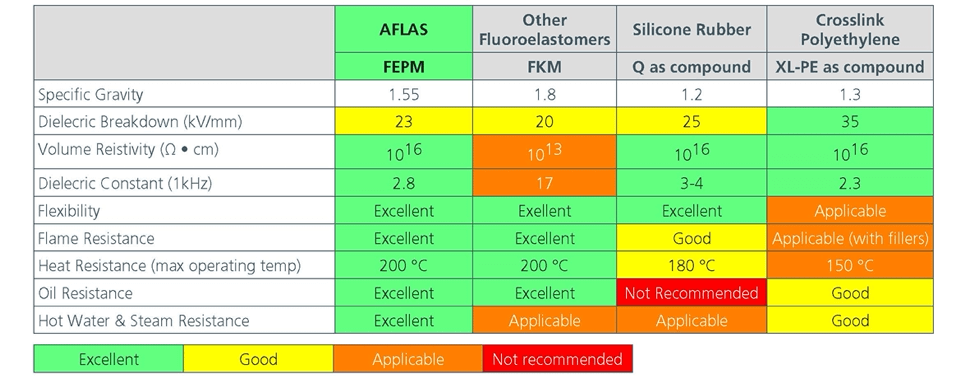

AFLAS is an extremely durable, nonflammable and high-temperature (200 °C) electrical insulation material. It provides superior performance in the harsh environment of electric and hybrid electric vehicle engines.

Better Formulation, Better Benefits

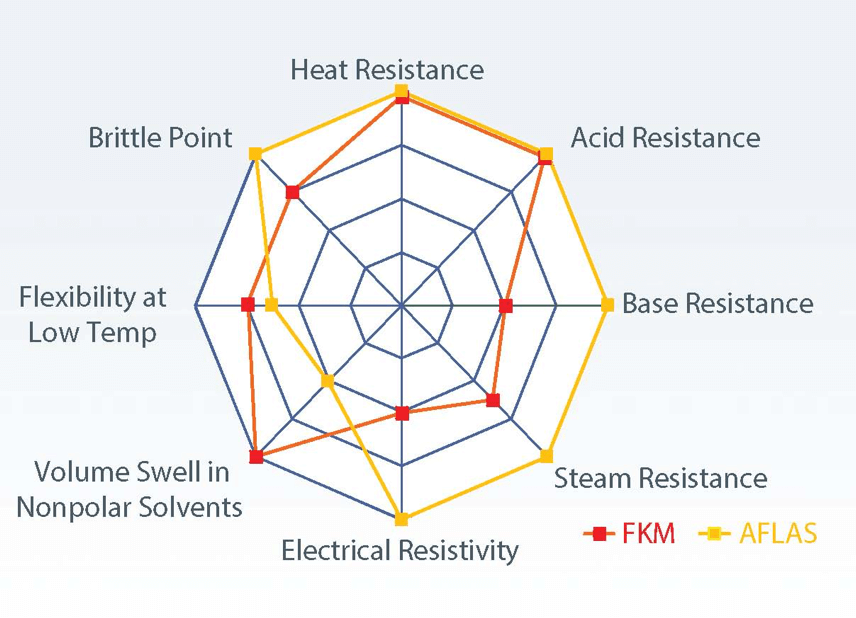

AFLAS fluoroelastomers are formulated as tetrafluoroethylene/propylene polymers. This formulation gives them unique properties over conventional FKM-type fluoroelastomers to excel in demanding automotive applications. AFLAS is classified by ASTM D1418 as an FEPM, which is different from other types of fluoroelastomers such as Viton™, DAI-EL and Tecnoflon®.

AFLAS works with aluminum and copper wire cores to produce cable systems that outperform traditional systems insulated with cross-linked polyethylene (XLPE). The polymer is ideal for applications where insulation needs to bend with the cable.

XLPE wire is a single-stranded copper or aluminum wire that is insulated with hydronic tubing composed of cross-linked polyethylene (XLPE) plastic. XLPE material is stiffer because it contains a lot of added Mg (OH)2 filler. It also offers limited heat resistance, which decreases its durability in EVs.

Performance Specs Tell the Story

An AFLAS cable outperforms XLPE with:

- Superior chemical resistance: It stands up well to attack from amine-containing additives in oils and transmission fluids.

- Outstanding steam resistance: It is unaffected by extended exposure to 200 °C steam.

- Unmatched electrical resistivity compared to FKM grades.

- Vibration resistance

- Heat resistance: It does not deteriorate even in prolonged exposure to 200 °C.

- Reduced weight

- Flexibility

Stands Up to Other Material Constructions

AFLAS outperforms standard fluoroelastomers (FKMs) and silicone rubber as an insulation material for high-voltage cabling in terms of thermal resistance, chemical resistance, strength, flexibility, heat and oil resistance, and volume resistivity. The chart below compares the performance of AFLAS fluoroelastomers to other materials.

Beyond Wire and Cable Insulation

In addition to its application as cable insulation for EVs, AFLAS is used in many automotive products and components including: oil seal/pinion shaft seals, oil cooler hose/turbocharger hoses, and cylinder-head gaskets. With its resistance to heat and additives contained in oils, it is the material of choice for components used in luxury cars, transportation vehicles, trucks and construction machinery.

AGC is the only manufacturer of FEPM in the world. Find out more about AFLAS fluoroelastomers at https://www.agcchem.com/products/fluoropolymer-resins/fluoroelastomers/ or contact AG***************@*gc.com.

Viton™ is a registered trademark of Chemours.

Technoflon® is a registered trademark of Solvay.

English

English