Reading Time: 4 minutes

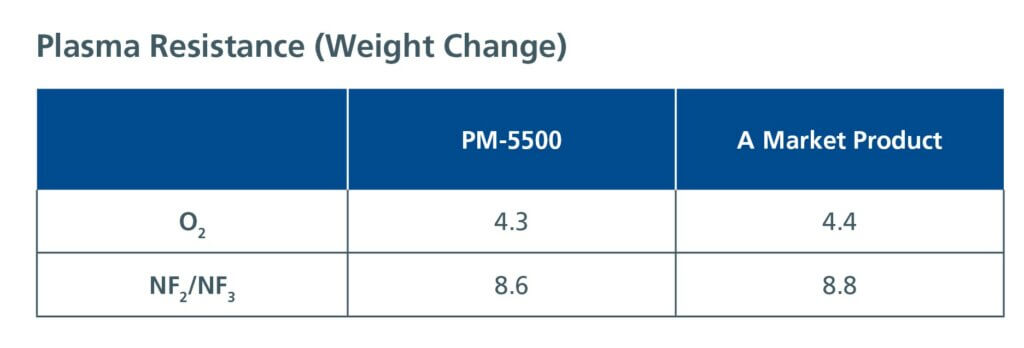

We recently added AFLAS® FFKM PM-5000 and PM-5500 grades to our line of fluoroelastomers. These perfluorinated elastomer grades meet the unique demands of semiconductor applications because they have high temperature durability, a high molecular weight and excellent resistance to O2 and NF3 plasma.

These grades build on the high-performance properties of other AFLAS FFKMs. They provide heat and chemical resistance and excellent electrical insulation to fabricate components that perform in aggressive and sensitive environments.

A Focus on High Temperature Durability

What sets the new AFLAS grades apart from other materials is their heat resistance. This is a critical feature for applications that require high thermal resistance 300 °C or higher, like those found in semiconductor plasma process applications. These new nitrile curable grades also have a high molecular weight that enables higher hardness without the use of fillers.

What Is FFKM? An Inside Look

FFKM is an enhanced version of FKM, a class of fluorinated carbon-based synthetic rubber known as fluoroelastomers. Derived from tetrafluoroethylene and perfluoroalkyl vinyl ether, this perfluoroelastomer compound excels in its resistance to temperatures, chemicals, oils, and solvents.

Exhibiting superior mechanical strength, excellent compression set, and high service temperatures, FFKM resins become the go-to material for fabricating parts for demanding applications.

Applications of FFKM in Semiconductor Manufacturing

- Chamber seals

- Cushioning for wafer transport

- Butterfly exhaust valves

- Centering O-rings in flanges

A Full Line of AFLAS Fluoroelastomer Grades for Semiconductor Applications

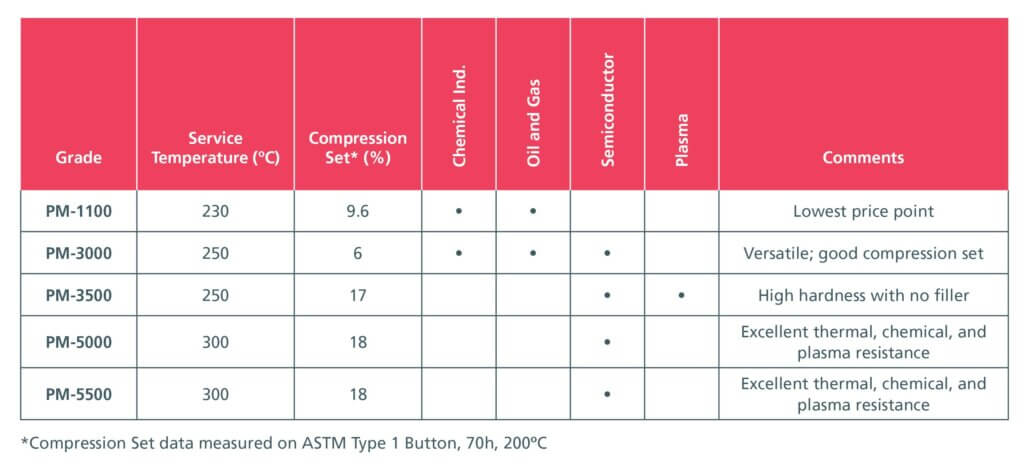

AGC now offers five grades of AFLAS FFKM elastomers that offer various price points, service conditions, compression sets, and purity levels. All are ultra-clean, have excellent plasma compatibility, chemical resistance and upper limit temperatures greater than 300 °C.

AFLAS PM-1100 and PM-3000 are our standard industrial grades. Both are peroxide cured with service temperature to 230 °C. These high molecular weight polymers provide superior toughness versus other FFKMs on the market.

AFLAS PM-3500 is a peroxide curable polymer that can achieve a hardness of 70 without adding fillers that increase the risk of contamination. This is great for semiconductor etching processes when resistance to plasma is critical. This polymer is exceptionally clean based on low trace metals evaluation. Its service temperature is rated at 250 °C.

AFLAS PM-5000 and PM-5500 are our nitrile curable polymers that have high temperature durability beyond 300 °C. Their O2 and NF3 plasma resistance make them ideal for semiconductor applications.

PM-1100: A Superior Replacement for FEPM/FKM Elastomers

- Chemical Performance: Offers improved chemical resistance compared to FEPM and FKM elastomers.

- Temperature Tolerance: Handles continuous temperatures up to 230°C and can withstand occasional peaks of 250°C.

- Affordability: As the most cost-effective FFKM grade, PM-1000 is perfect for general applications.

PM-3000: Engineered for Higher Temperatures

- Heat Endurance: Supports a continuous service temperature of 250°C, with peak temperatures reaching 270°C.

- Durability: Parts made from this grade resist wear and outlast many other materials in critical applications.

- Efficiency: With an improved compression set, PM-3000 maintains pressure longer, reducing maintenance requirements.

- Versatility: Ideal for creating seals, gaskets, and other parts in the chemical processing, semiconductor, and oil and gas sectors.

PM 3500: Superior Hardness for Semiconductor Plasma Process Applications

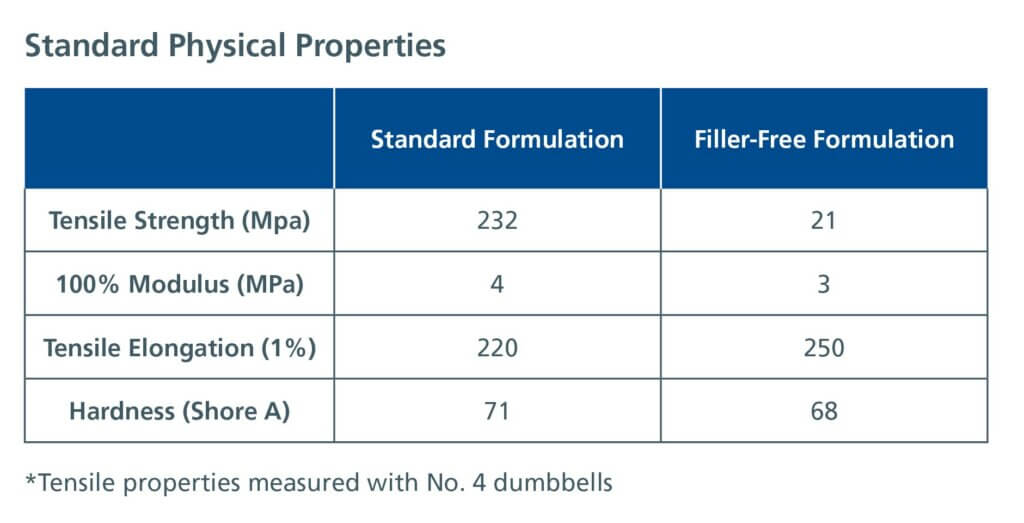

- Hardness: Achieves a Shore A hardness of 70 without fillers, preventing contamination in clean rooms.

- Plasma Resistance: Suitable for the etching process in semiconductor manufacturing.

- Purity: Designed for semiconductor applications that demand high purity.

- Heat Resistance: Provides service temperatures up to 300 °C or higher, perfect for chamber seals, window, door, and valve seals, and water transport cushioning in semiconductor manufacturing.

Photo by Harrison Broadbent on Unsplash.

AFLAS PM-5000: For Low Compression Set and Adhesive Force

- High Thermal Resistance: High Temperature durability beyond 300 °C makes it suitable for demanding applications like O-rings and gaskets in the etching process of semiconductor manufacturing

- World-class, low trace metal content

- Exceptional Resistance: Offers excellent resistance to chemicals, oil, and solvents.

- Particle-Free Hardness: Achieves hardness at 68 without fillers that cause particle generation.

- Excellent Resistance: Resistant to O2 and NF3 Plasma

- Nitrile Curable

- Ideal for O-rings, Gaskets, Molded components

AFLAS PM-5500: Tailored for Higher Molecular Weights

All the advantages of PM-5000, plus:

- Higher molecular weight: Enables higher hardness

- Low particle generation: fillers not needed to achieve hardness

Applications of FKM in Other Industries

The resilience and durability of FFKM resins also make them ideal for harsh environments found in:

- Chemical Processing: Withstanding aggressive chemicals and processes.

- Industrial Equipment: Offering endurance in rugged conditions.

- Food Handling: Ensuring compliance with hygiene standards.

- Pharmaceutical: Meeting precise and controlled specifications.

- Automotive Industries: Providing reliability in various automotive applications.

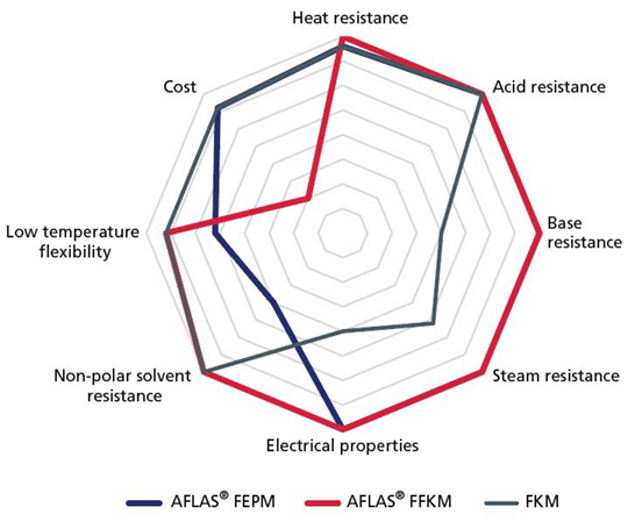

O-rings, seals, and other parts formulated from these resins resist wear and last longer in critical applications than other materials. The graphic below compares the properties among AFLAS FEPM, AFLAST FFKM and FKM.

AFLAS PM-5000 and PM-5500 are nitrile curable for easy handling and processing. Fully fluorinated, each grade exhibits high sealing performance in different aggressive chemical environments. Whether it’s ultra-clean applications in semiconductor manufacturing or high thermal resistance in petrochemical processing, our elastomers provide the quality and reliability you require.

We offer tailored solutions that cater to various industrial needs. AGC continues to formulate new grades of AFLAS FFKMs to meet future challenges for evolving applications and markets. Explore our products today and find the perfect match for your specific needs.

English

English