Consider these Fluoro Material Alternatives to THV for Wire and Cable Applications

Reading Time: 3 minutes

Fluoro materials are available that can be used instead of THV in demanding applications. THV is a widely used fluoropolymer used for safeguarding wire and cable jackets against physical damage and chemical deterioration. THV is already in short supply, leading to long lead times and higher prices.

To make matters worse, 3M, the sole producer of THV, announced plans to cease production of THV by 2025. This is expected to exacerbate future supply constraints for this material.

AGC Chemicals offers two readily available products that can be used as alternatives to THV including:

- Fluon+™ AR Flexible Compounds

- Fluon® LM ETFE

Both fluoropolymers exhibit the chemical resistance and strong mechanical characteristics similar to those of THV. Some grades even surpass THV in terms of durability, lower melting points, and reduced flexural modulus. Depending on their unique formulations, each fluoropolymer presents specific benefits for wire and cable applications.

The Scoop on Fluon+ AR Fluoro Materials

Fluon+ AR Flexible Compounds are blends of ETFE with fluoroelastomers that offer a similar combination of performance and processing advantages as THV. While possessing the desirable properties of ETFE, Fluon+ AR compounds are more flexible than other fluoropolymer materials and are melt processable by conventional extrusion from pellet feeds.

Their flexural modulus is lower than neat ETFE and close to that of THV, as shown in the chart below. In addition, Fluon+ AR grades have higher temperature resistance and lower processing temperatures than standard ETFE.

The benefits of Fluon+ AR Products include:

- Exceptional resistance to chemical corrosion

- More rugged than standard fluoroelastomers

- A broad service temperature range, extending up to 200°C

- Comparable or even superior flexibility to THV

- Customizable compounding options

- Favorable dielectric properties

Facts on Fluon LM ETFE

Due to lower melting points, Fluon LM-ETFE modified resins can be processed at temperatures 50°C below those required for standard ETFE.

This wider temperature range enhances processability, flexibility, and strength, enabling continuous use at temperatures up to 180°C. LM-ETFE also provides improved heat and chemical resistance, reduced susceptibility to stress cracks, enhanced thermal stability, and greater transparency than standard ETFE.

Advantages of Fluon LM ETFE vs. standard ETFE:

- Greater transparency

- Increased flexibility

- Higher extruder throughput rates

- Improved resistance to stress cracking

- Reduced flammability

- Enhanced physical toughness

- Favorable dielectric properties

Fluon LM-ETFE is an ideal choice for wire and cable coatings because of its outstanding electrical insulation properties across various temperature ranges and its exceptional mechanical strength, particularly in terms of flex life.

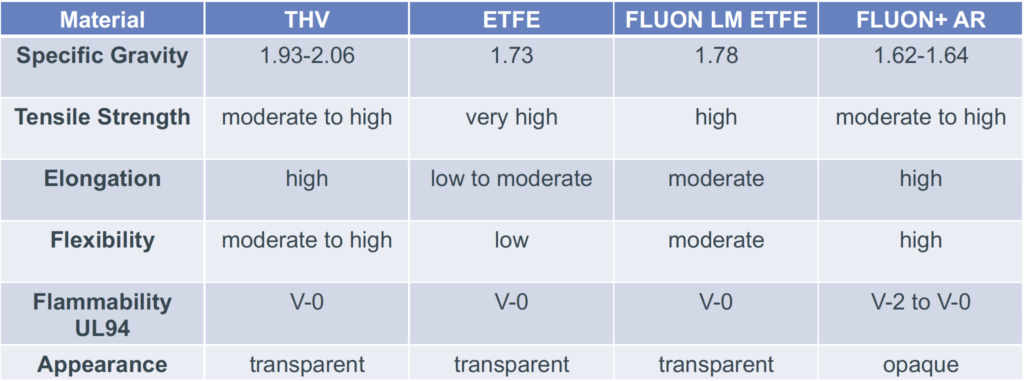

Fluon LM ETFE vs Fluon+ AR vs. THV

The table below shows how Fluon+ AR Flexible Compounds and Fluon LM ETFE surpass ETFE while serving as viable replacements for THV.

Which is Best for Wire & Cable Applications?

While serving as replacements for THV as wire and cable coatings, Fluon+ AR Flexible Compounds and Fluon LM ETFE meet different requirements in these applications. All solutions provide improved flexibility over traditional ETFE. The table below outlines the different attributes that can aid in their selection.

| Fluon+AR | Fluon LM ETFE |

| Ultra-flexible wire and cable or tubing | Flexible wire and cable or tubing |

| Applications requiring opacity | Applications requiring good transparency |

| Custom-tailored solution to enhance physical properties, service temperatures, etc. | Applications that require good abrasion resistance and toughness. |

| Chemical resistance | Fuel and chemical resistance |

| Heat resistance can be enhanced by radiation curing | Excellent electrical and insulating properties in a wide range of temperatures. |

Now is the time to prepare for shortages in THV and find alternatives that match or exceed current application requirements. Download this PPT presentation for more details. Contact AGC Chemicals to find the right performance fluoro material and grade for your wire and cabling needs.

AGC Chemicals Americas offers the broadest range of high-performance fluoropolymers in the world including fluoroelastomers, PTFE, PFA and ETFE resins, fluoropolymer compounds, and advance materials. Find out more about the company’s products and industry solutions at https://www.agcchem.com/.

English

English