Reading Time: 3 minutes

This blog post explores the role of microspherical silica as excipients in pharmaceuticals, foods and nutritional supplements—helping to refine formulations for enhanced performance and product stability.

What are Excipients and Why are They Important?

Do you know what’s in your medications beyond the active ingredients? In addition to active pharmaceutical ingredients (APIs), most capsules and tablets also contain inactive ingredients known as excipients.

While excipients have no pharmacological or nutritional effect, they serve vital functions as fillers, carriers, preservatives, binders and processing aids. Excipients improve manufacturability, consistency, texture and shelf life. In fact, they are so integral to drug production that excipients often comprise 80 – 90% of a finished pharmaceutical product. In nutritional supplements and functional foods, excipients also help enhance product appearance, flow and stability.

Silica as a Preferred Excipient

Among the many excipients used today—such as fumed silica, colloidal silica, surfactants and minerals—silica-based excipients stand out for their natural origin, chemical inertness and safety profile. RESIFA™ SOLESPHERE™ high purity silica, developed by AGC, delivers significant functional benefits when used as excipients in pharmaceutical, nutraceutical and food applications.

What is SOLESPHERE silica?

SOLESPHERE fine silica is a high-purity (99%) superfine white powder made of particles with near-perfect spherical shapes and uniform pore structures. This microspherical morphology and narrow particle size distribution enables superior absorption, enhanced flowability and consistent dosage forms.

Key Benefits of SOLESPHERE Silica as Excipients:

- Exceptional absorption capacity of ~150–400 mL/100g to protect active ingredients from moisture and UV exposure, and to enable powdering of liquids.

- High pore volume and surface area (40–800 m²/g) allow small volumes of silica to carry large loads of active ingredients.

- Particle size range (3–20 µm) supports tailored applications and use as a time-release agent.

- Adjustable pore structure and high surface area enable advanced drug delivery applications.

- Excellent flowability enhances viscosity and processability in powder formulations.

- Uniform spherical shape contributes to consistent dosage units.

- Superior anti-caking properties improve powder flow, enhancing manufacturing efficiency of powder formations.

- Narrow size distribution ensures even dispersion in the final product.

- Porosity variety enables multiple options in manipulating release control.

- Stable shelf life preserves active ingredients, protects from moisure and maintains long-term product efficacy and shelf life.

Applications for SOLESPHERE excipients

AGC’s high purity silica are recognized by several certifications including ISO 9001, HALAL and Kosher and FDA. Ideal applications include:

- Encapsulating Liquids/Oils: SOLESPHERE silica encapsulates liquid into powders via its high oil absorption capacity (up to 400 mL/100g.) It performs reliably in food and pharmaceutical applications.

- Powdering Active Oils: By converting oils (e.g., olive oil) into powder, SOLESPHERE silica enables incorporation into dry formulations. When mixed with an oil in the right ratio, its high porosity and surface area trap oils effectively, creating free-flowing excipient powders.

- Enhancing Active Ingredient Performance: Functions as a time-release agent, enabling time-release delivery and enhancing the bioavailability and effectiveness of APIs.

- Manufacturing Aid: With excellent flow and a narrow particle size distribution, SOLESPHERE excipients support uniform dosage forms and enhance mass production efficiency by carrying more active ingredients than conventional excipients.

- Emulsifier Functionality: Assists in dispersing water-soluble components into oils and vice versa. Improves the usability of topical actives and enhances formulation acceptance.

Available grades of SOLESPHERE Silica Excipients

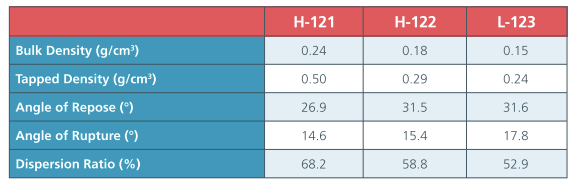

AGC offers a variety of grades of SOLEPHERE silica excipients tailored to specific applications based on excipient role, dosage form and active ingredient compatibility. Four examples include:

- SOLESPHERE H-33: 3 µm spherical particles with a surface area of 700 m²/g and moisture absorption of 400 mL/100g.

- SOLEPHERE H-121: 12um particles with 800m2/g surface area and moisture absorption capacity of 150 mL/100g.

- SOLESPHERE L-123: 12 µm size with 50 µm pore diameter, offering enhanced absorption at 400 mL/100g.

Excipients are far more than inactive fillers—they’re critical components that determine the quality, consistency and functionality of pharmaceutical, food and nutraceutical products. With its high purity, microspherical design and industry certifications, SOLESPHERE silica stands out as a next-generation excipient that enhances product formulation and production efficiency.

For more information on SOLESPHERE high purity silica for excipients, visit our web page or make a product inquiry.