-

AGC Chemicals Americas

-

English

English

- Customer & product inquiries: 1-800-424-7833

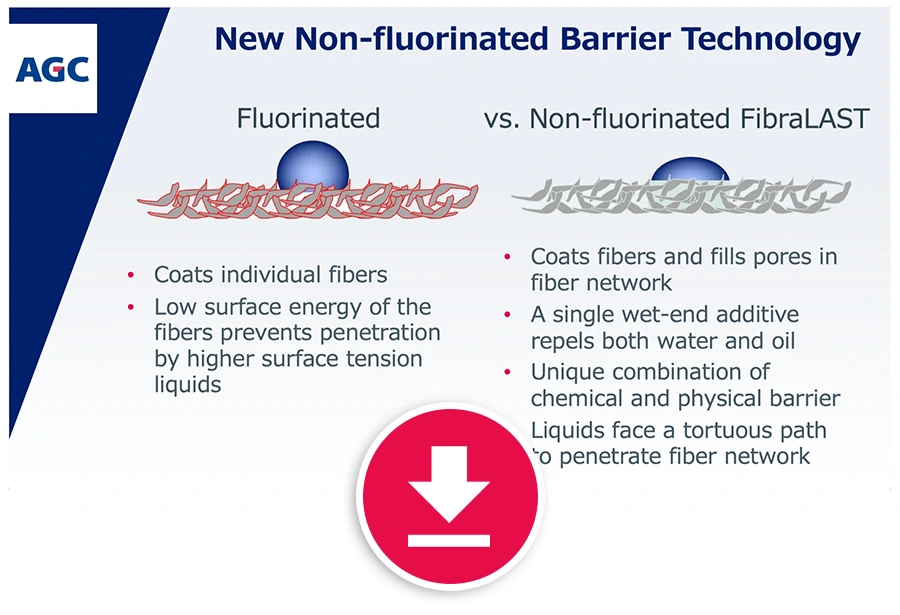

FibraLAST® Non-Fluorinated Barrier Technology

Non-fluorinated finishes for nonwoven fabrics and technical textiles that protect from both oils and water. Non-PFAS sizing additives that protect paper products from water and hot oil.

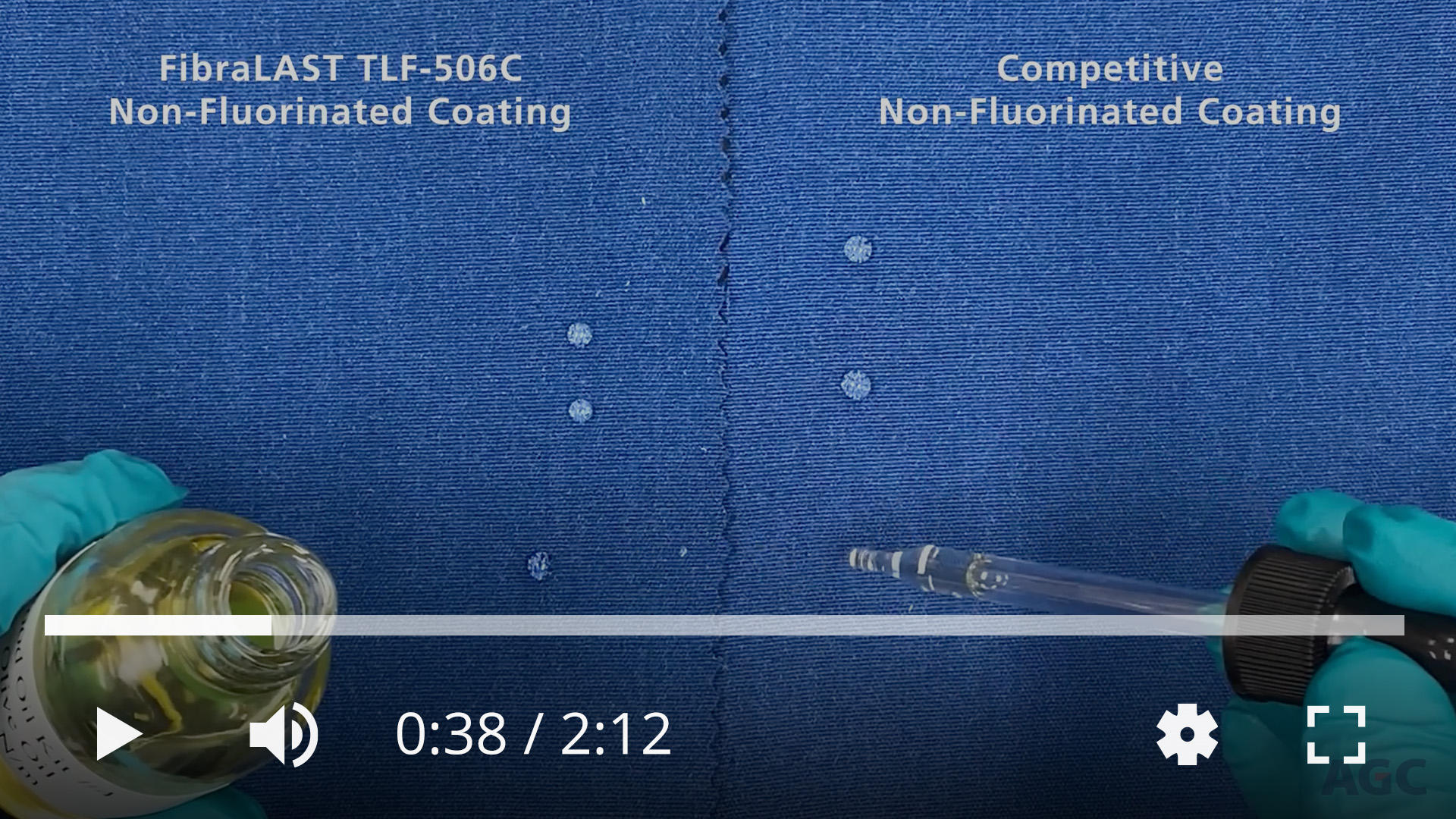

Non-fluorinated oil/water repellents for technical textiles

FibraLAST® non-fluorinated oil/water repellents are ideal for technical textiles. When applied as a thin polymeric coating on textiles, they form a microscopically rough texture that acts as a chemical barrier. This treatment enables textiles to repel oil-based stains and fluids, causing them to bead up for easy cleaning.

These new coatings are ideal for:

- Industrial fabrics

- Upholstery

- Automotive textiles

- Medical textiles

- Filtration

- Awnings and marine textiles

They can be applied via dipping or industrial spray-coating and provide a high-performance, sustainable alternative to fluorinated repellent technologies.

Non-fluorinated oil/water repellents for nonwovens

FibraLAST non-PFAS oil/water repellents are ideal for use on nonwoven fabrics. When applied as a thin polymeric coating, they form a microscopically rough texture that acts as a chemical barrier. This treatment enables nonwovens to repel oil-based stains and fluids, including bodily fluids, causing them to bead up for easy cleaning.

These innovative coatings are ideal for:

- Disposable medical products

- Automotive nonwoven products

- Filtration products

They can be applied via dipping or industrial spray-coating, offering a high-performance, sustainable alternative to fluorinated repellent technologies.

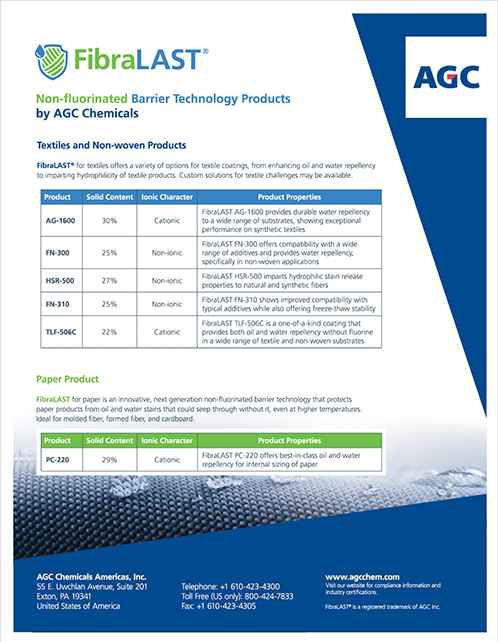

Non-fluorinated sizing additives for water and oil proof packaging

FibraLAST non-fluorinated sizing additives are made with natural materials that protect packaging from both water and oil. They prevent bleed-through of high-temperature liquids and food oils through the molded fiber, achieving 80 °C water and oil holdout performance.

They are FDA compliant for contact with food of all types and ideal for molded, formed fiber and cardboard products such as:

- Fast-casual bowls

- Fast-casual plates

- Take-out containers

- Pizza boxes

Since they are applied to the pulp before fabrication, no additional equipment of process is required. They can be used as an alternative to traditional oil sizing products, which are spray-coated on products after fabrication. Pulp and paper mills can cost-effectively enhance their products with a single wet-end additive.

Markets

Paper Products:

- Non-fluorinated chemistry

- Excellent alternative to traditional oil sizing product grades

- Designed for wet-end processes

- Designed to be applied to pulp instead of spray coating end product

- Protects at high temperatures, even at 80 °C

- FDA compliant for food contact

- Kosher-approval pending

- Excellent water repellency and hydrophilic stain release properties

- Offers compatibility with a wide range of additives

- Made in the USA

- Patented technology

Technical Textiles:

- Non-fluorinated chemistry

- Ideal alternative to fluorinated repellent technologies

- Designed for dipping or industrial spray-coating applications

- Applied to finished end product

- Minimal mark-off and chalking

Nonwoven Fabrics:

- Non-fluorinated chemistry

- Ideal alternative to fluorinated repellent technologies

- Designed for dipping or industrial spray-coating applications

- Compatibility with various binders in wet end applications

- Oil and water repellency

- Alcohol repellency including IPA

- Excellent hydrostatic head properties

- Anti-static compatibility

Paper products:

- Molded and formed fiber

- Cardboard and pizza boxes

- Fast-casual bowls, plates, and containers

Technical textiles:

- Industrial fabrics

- Upholstery

- Automotive textiles

- Medical textiles

- Filtration products

Nonwoven Fabrics

- Disposable medical products

- Automotive nonwoven products

- Filtration products

Click here to request an SDS sheet.

- Performance evaluation services

- Testing for water and oil repellency

- Hydrostatic pressure testing

- Static decay testing

- Surface resistivity testing

- Exposure testing

Call our fluoropolymer experts to discuss your specific needs.

Latest from the Blog

AGC Supports Key Trade Associations to Lend Expertise in Fluoropolymer Technology

AGC Chemicals Americas, a leading name in fluoropolymer technology, is a proud member of many trade associations. The company actively collaborates with them to share its expertise in fluoropolymer technology with resins and specialty materials, including films, and coatings. By…

Read about this topic...New Non-Fluorinated Barrier Technology

There has never been a non-fluorinated sizing additive that could protect paper products like fast-food containers from both water and food oils. That has changed with AGC’s development of a new wet-end additive that can be added to fibers during…

Read about this topic...AGC’s Commitment to Quality: Bringing Your Ideas to Life Through Specialized Testing Services

As a leading global supplier of fluorochemicals and materials, AGC is committed to upholding the highest quality standards across all of our product lines. But you need to consider more than just quality when selecting a product to add to…

Read about this topic...