Reading Time: 3 minutes

Components inside electronic devices can rust when exposed to contaminants and moisture. This corrosion can reduce performance and cause electrical shorts and device failure. Transparent fluoropolymer coatings offer the insulation properties of standard PTFEs to protect sensitive components while providing high optical transparency.

When selecting coating materials for electronics, the service environment, component life span and the coating cost are important considerations. While many coating options exist on the market, many are not suitable for optical products and other electronics that require full light to function optimally. Transparent fluoropolymer coatings allow maximum light transmission while protecting against chemicals, oils and water.

Conventional vs. Transparent Fluoropolymer Coatings

Conventional fluoropolymers, like PTFE (polytetrafluoroethylene)

resins, impart strength, durability, heat and chemical resistance and high-performance electrical insulation. These characteristics help extend the lifespan of components and improve their fire safety. However, they are not transparent.

AGC developed transparent fluoropolymer coatings (called CYTOP™) that possess the same thermoplastic characteristics as PTFE but exhibits high optical transparency and good solubility in certain fluorinated solvents. More transparent than acrylic resin, CYTOP offers a transparency level equivalent to a quartz even in the UV-C (200 – 280 mm) region but at a higher workability.

These additional properties provide new options for many industries, especially as a coating material for electronic components, such as circuit boards.

Composition of Transparent Fluoropolymer Coatings

CYTOP is an amorphous fluoropolymer with a unique molecular structure comprised of non-crystalline fluoropolymer particles dispersed in a special fluorinated solvent. With a structure completely different from other fluoropolymers, it exhibits a low refractive index equivalent to water, no fluorescence, low coefficient of optical dispersion and good lamination properties.

With a visible light transmission ratio of more than 95%, this transparent fluoropolymer enables manufacturers to make thin film coatings that generate anti-reflective properties over optical components for eyeglasses, photo masks and optical fiber, for example.

Types of CYTOP

CYTOP is available in three grades with different solvent types and boiling points. Each type has a unique functional group at both ends of the polymer that make it ideal for specific applications.

Type A

Metal and glass are coated using a silane coupling agent together with this type of CYTOP. Type A is used with a special primer to coat plastics. Transparent to visible light, it is ideal for use on anti-reflection film and optical membranes. Type A CYTOP also works as a water and oil repellent and an electric insulator.

Type M

Type M CYTOP is used in one-step coating processes for metals and glass. It is used as a protective layer, a water and oil repellent or an electric insulator.

Type S

This type exhibits a high transparency for a wide range of light, from visible to ultraviolet (UV). It also imparts a very tough UV resistance as well as resistance to adhesion. Type S CYTOP is ideal for coating pellicles and optical materials, and can be used to facilitate mold release.

Coating methods

While most fluoropolymers are insoluble and require a baking process to adhere onto a substrate, CYTOP transparent fluoropolymers are highly soluble and dissolve in special fluorocarbon solvents. Eliminating the baking process makes it easy to coat onto a substrate.

Users can customize coating thickness. Depending on the amount of solvent, CYTOP can be used in thin film coatings to a thickness of a few sub-microns.

CYTOP can be coated in three different ways. Coating techniques depend on the base material, shape, and expected thickness of the coating.

- Spin-coating to coat flat and circular boards.

- Dip-coating used to coat any type of board

- Potting method to coat any type of board

Uses of CYTOP Transparent Fluoropolymer Coatings

High transparency fluorine coating material CYTOP demonstrates high transparency in a range between ultraviolet and near infrared. Serving as a transparent PTFE, this amorphous fluoropolymer is used to coat:

- Optical fibers

- Peripheral components

- Graded-index optical fibers

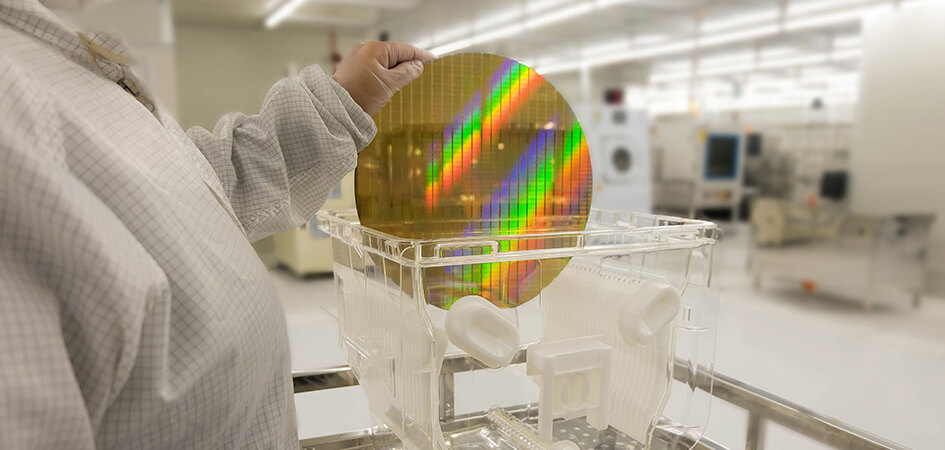

- Inter-level dielectric layer for semiconductors

- Pellicles

- Protective coating for semiconductors

- Non-autofluorescence hydrophobic coating of microfluidics

- Hydrophobic coating of Electrowetting devices

- Antifouling coatings for photomasks

- Optical film

- Anti-reflective displays

- Insulation materials for displays

- Deep ultraviolet LED

- Transparent anti-corrosion

In addition to its use in electronics and telecommunications, CYTOP is touted as the next-generated material with future uses in LED encapsulants and ultrafast optical fiber

For more information and assistance in selecting the right CYTOP transparent fluoropolymer coating for your specific application, please visit https://www.agcchem.com/products/high-performance-coatings/cytop/ or call 800-424-7833.

English

English