The Advantages of Replacing Traditional FKM and FFKM Rubber-to-Metal Seals with AFLAS® Fluoroelastomers

Reading Time: 2 minutes

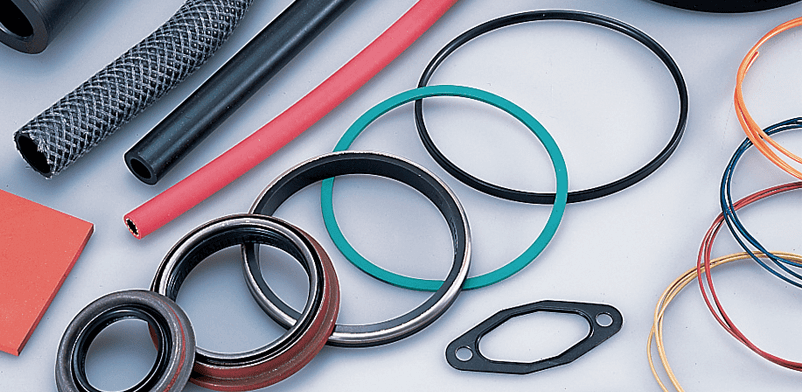

FKM is the ASTM designation for a class of fluorinated, carbon-based synthetic rubber, commonly known as fluoroelastomers, which were introduced in the 1950s. FKMs exhibit impressive heat resistance as well as resistance to high pressures, chemicals and other fuels. These performance qualities made them an ideal material for high-performance seals, O-rings and gaskets used in automotive, aerospace and energy applications.

Since the arrival of FKMs, formulators have developed a wide variety of fluoroelastomers for rubber-to-metal sealing. The next material to arrive was FFKM (perfluoroelastomer) which contains higher amounts of fluorine and features temperature ratings up to approximately 325 °C. The first commercially available FFKM seal was produced in the late 1960s.

In 1975, AGC Chemicals Americas introduced AFLAS®, a new pioneering fluoroelastomer based on an alternating copolymer of tetrafluoroethylene (TFE) and propylene.

AFLAS is a great polymer option for sealing applications, and is generally less costly than FFKMs like Kalrez®. Its unique polymer structure offers properties not possible with any other elastomer on the market. Different AFLAS grades provide customizable base resistance, electrical resistivity, curability and extrusion processability.

Superior Rubber-to-Metal Sealing

AFLAS is an ideal material for shaft seals, cylinder head gaskets or oil seals that are bonded to metal because it provides solvent, ozone and steam resistance. It also provides sufficient chemical resistance for many applications. For this reason, seals and other components made from AFLAS maintain their integrity when used in oil and gas exploration, chemical processing and under-the-hood automotive applications. It is often possible to replace costly seals made from FFKMs with AFLAS seals.

When selecting polymer materials for seals, including AFLAS, it’s important to take into consideration the specific chemicals to which the seals will be exposed.

A variety of AFLAS grades are available including:

- 150 Series –The standard grade, low-viscosity polymer to help with extrusion and improved mold flow.

- 100 Series – The high-strength grade, high-viscosity polymer that helps with explosive decompression for downhole applications.

- AFLAS 200P – A specialty base-resistant FKM for improved performance at cold temperatures.

- AFLAS PM-1100 and PM-3000 – An FFKM series of polymers for ultra-hot continuous temperatures up to 230 °C and 250 °C, respectively.

Compounding and Formulation

AFLAS fluoroelastomers are easily compounded by standard processing equipment, such as Banbury® mixers and open two-roll mills. The resulting polymer compounds are then fabricated into finished parts and shapes using:

AFLAS fluoroelastomers are easily compounded by standard processing equipment, such as Banbury® mixers and open two-roll mills. The resulting polymer compounds are then fabricated into finished parts and shapes using:

- Press Molding

- Injection Molding

- Extrusion

- Calendaring

Below is a common formulation for creating a 75 Durometer black AFLAS seal:

Read more about AFLAS Sealing Applications

AFLAS® fluoroelastomers are the material of choice for parts and components that need to perform reliably in the world’s harshest environments. To learn more about AFLAS fluoroelastomers sealing applications, as well as recommended methods of sealing, click here.

English

English