AGC Chemicals Americas

-

English

English

- Documentation

- Resources

- Blog

-

Customer & product inquiries: 1-800-424-7833

Customer & product inquiries: 1-800-424-7833

AGC Chemicals Americas

English

English

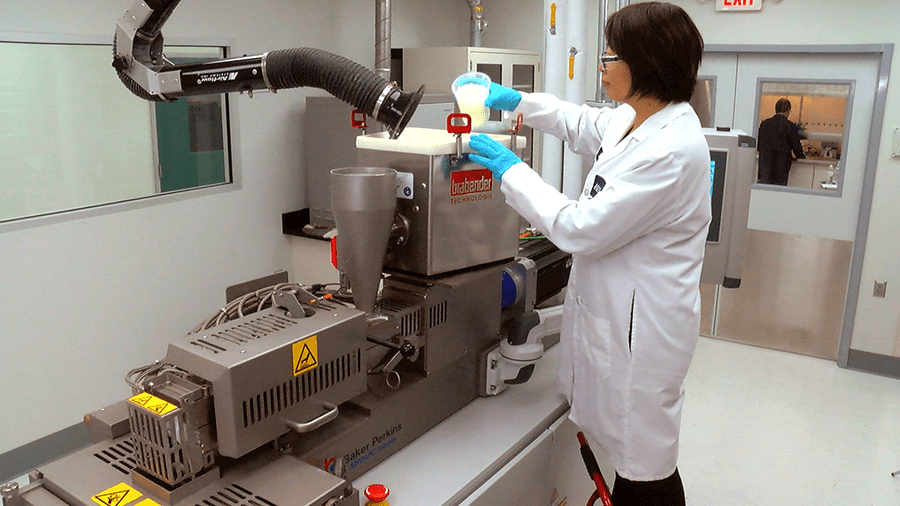

EXTON, Pa., May 4, 2017 – AGC Chemicals Americas, a leading global supplier of high-quality fluorochemicals and materials, has expanded its LUMIFLON® resins testing lab in Exton, Pennsylvania. The company has added state-of-the-art equipment and services to help formulators develop innovative powder coatings for many markets including building, industrial maintenance, aerospace and automotive.

For many years, the AGC resins laboratory has tested the weatherability of coating systems formulated with LUMIFLON fluoropolymer resins. Now the lab has the technology and services required to test fluoropolymer-based powder coating systems, which are growing in popularity due to their long life and environmental advantages. New services include cross section coating morphology testing using SEM/DMX coupled with microtome. New equipment includes:

“Powder coatings are an environmentally friendly technology that is rising in popularity for long-life coatings,” said Tatsuya Masuda, managing director at AGC Chemicals Americas. “Our LUMIFLON resins testing lab is now fully equipped to assist coating manufacturers in developing new formulations.”

The LUMIFLON resins testing lab also has all the equipment required to mix and grind pigments and apply traditional coatings to a variety of substrates to test physical properties such as impact resistance, tensile, gloss, viscosity, pencil hardness and color. Lab technicians can also conduct accelerated corrosion tests and outdoor testing for real world weathering exposure.

AGC is offering tours of the new facility so that customers, prospects and members of the scientific and local community can see the laboratory and equipment operating in real-time. For more information, contact Kristin Carlin at kristin.carlin@agc.com.

LUMIFLON FEVE is the first solvent-soluble fluoropolymer resin for coatings that can be cured at room temperature or at elevated temperatures. LUMIFLON resins, used in topcoats, are ultra-weatherable, and maintain their excellent appearance on buildings, bridges, and other structures, as well as on aircraft, automobiles, and solar panels. LUMIFLON coatings protect steel, aluminum and other metals as well as concrete from degradation by UV light, wind and rain, and corrosion. For more information on the latest innovations related to LUMIFLON FEVE resins, please go to www.lumiflonusa.com.

AGC Chemicals Americas is a global subsidiary of AGC Inc., a multinational corporation and one of the world’s largest manufacturers of glass, electronic displays and chemical products. Headquartered in Exton, Pennsylvania, including a state-of-the-art technology center, AGC Chemicals Americas maintains manufacturing operations in nearby Thorndale, Pennsylvania, a satellite sales office in Guaratingueta, Brazil, and warehouses located throughout North America. www.agcchem.com