EXTON, Pa., May 21, 2020 – AGC Chemicals Americas Inc. announces its membership with Gasket Fabricators Association, a trade organization of companies that provide custom-fabricated components and services to the gasket industry. AGC is a leading manufacturer of high-performance fluoroelastomers and fluoropolymers for gaskets, seals and other components that must withstand demanding operating conditions.

“Becoming an active member in the GFA gives us an opportunity to share information about the performance benefits of fabricating parts and components with advanced fluorine-based products,” said Drew D’Agosta, director of sales and marketing, AGCCA. “In return, we will benefit from developing strategic relationships with industry professionals in order to solve fabrication and performance challenges and exchange ideas toward developing materials science solutions for the marketplace.”

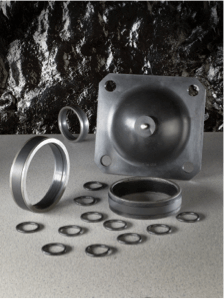

AFLAS® Fluoroelastomers from AGC are ideal for parts and components that need to perform reliably in harsh environments. They provide outstanding performance properties like resistance to heat, chemicals, fuels, acids, bases, solvents, ozone and steam.

AGC’s Fluon+™ Filled PTFE compounds improve the performance properties of parts operating in severe conditions. They impart characteristics that are vital for components such as bearings, seals and gaskets used in applications where they need to withstand ongoing heat, pressure and dynamic environments.

For information about the Gasket Fabricators Association, visit www.gasketfab.com.

About AGC Chemicals Americas, Inc.

AGC Chemicals Americas is a global subsidiary of AGC Inc., a multinational corporation and one of the world’s largest manufacturers of glass, electronic displays and chemical products. Headquartered in Exton, Pennsylvania, including a state-of-the-art technology center, AGC Chemicals Americas maintains manufacturing operations in nearby Thorndale, Pennsylvania, a satellite sales office in Guaratingueta, Brazil, and warehouses located throughout North America. www.agcchem.com

English

English