Reading Time: 3 minutes

Lithium is a critical raw material for clean energy technologies. It is used to produce lithium-ion batteries that power electric vehicles and energy storage systems. As more companies transition to clean energy, demand for lithium is projected to rise from about half a million metric tons in 2021 to 3 million metric tons by 2030, according to McKinsey & Company. To meet this demand, producers must improve operational efficiency. New technologies such as direct lithium extraction (DLE) and membrane electrolysis offer faster, cleaner pathways than traditional methods.

Primary Methods of Lithium Production

Lithium is a metal that occurs primarily in spodumene and brine pools. Conventional extraction involves crushing rock or evaporating water from brine. However, these methods are energy-intensive and release significant carbon emissions. Alternative approaches can be more efficient and consume fewer resources.

Common methods of lithium production include:

Hardrock Mining

Hardrock mining uses heavy machinery to crush spodumene ore and grind it into powder. The powder is then roasted and leached with sulfuric acid to separate the lithium. On average, mining releases about 15 tons of carbon dioxide for every ton of lithium produced. It also creates open mine pits that can destroy local habitats and harm the environment.

Solar Evaporation

Solar evaporation accounts for nearly half of global lithium production. Pumps draw brine from aquifers into large ponds, where the water evaporates and lithium remains. This method has a relatively low recovery rate of 40% to 60% and can take up to 18 months to reach the target concentration of lithium. Once the brine evaporates, the soil becomes barren and unable to support plant life.

Direct Lithium Extraction (DLE)

Direct lithium extraction (DLE) offers a cleaner, more efficient way to produce lithium. One DLE method uses ion-exchange membranes and electrolysis to quickly separate lithium from brine. An electrical current applied to the brine pushes lithium ions through the membrane, which filters out impurities to form a concentrated lithium solution.

The key benefits of direct lithium extraction include:=

- Lower carbon emissions: DLE technologies release about 50% fewer emissions than many other conventional methods. They use significantly less energy than mining, which requires extreme temperatures to heat ore.

- Lower water consumption: DLE consumes less water than evaporation ponds and achieves high recovery rates of 90%, extracting more lithium per liter of brine. Unused water can be returned to aquifers, minimizing environmental impact.

- Faster production: Manufacturers can extract lithium in as little as two weeks, compared with more than a year for evaporation ponds to completely concentrate lithium.

Lithium Hydroxide Production

Concentrated lithium brines from DLE or other methods are further processed into useful products like lithium hydroxide. Traditionally a multistep chemical precipitation process is required. Membrane electrolysis offers an alternative, green pathway.

Key benefits of membrane electrolysis for the production of LiOH include:

- Smaller carbon footprint and compatibility with renewable energy

- High purity battery-grade LiOH (>99.5%)

- Reduced reagent costs and waste streams

Introducing AGC FORBLUE™ Membranes for Lithium Production

AGC Chemicals Americas offers a variety of FORBLUE™ membranes designed to meet different lithium processes, including concentrating lithium in direct lithium extraction and producing lithium hydroxide. These durable membranes provide strong chemical resistance and reduce energy requirements. They are available in the following lines:

SELEMION Membranes

FORBLUE SELEMION hydrocarbon membranes are ideal for lithium extraction. They dilute and concentrate ionic materials with electro diffusion/dialysis. A direct current or concentration gradient drives lithium ions through the membrane, creating a concentrated lithium solution. Available in nine grades, SELEMION membranes suit a wide range of lithium applications. Their key benefits include:

- High ion selectivity

- Thin membrane

- Low resistance

- High strength

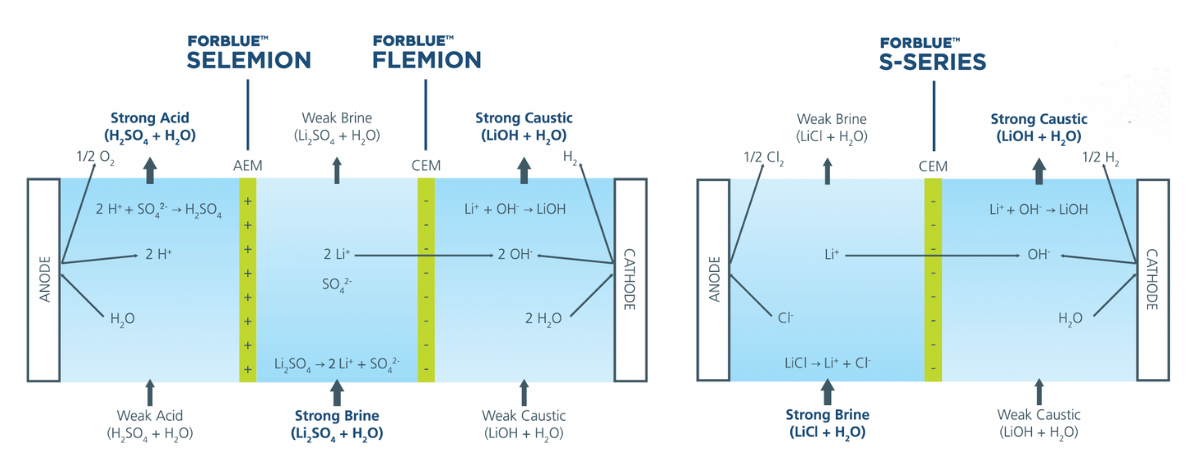

S-SERIES and FLEMION Membranes

FORBLUE S-Series and FLEMION grades are fluorinated cation exchange membranes used to produce high-purity lithium hydroxide or recycle lithium battery streams via electrolysis. The high ion selectivity improves product purity and increases recovery rates. Made from fluorinated resins, these durable membranes ensure chemical and thermal durability. They reduce energy use by minimizing electrical resistance.

Enhance Lithium Processing With Advanced FORBLUE Membranes

AGC’s FORBLUE membranes enhance lithium processing by reducing energy consumption, improving durability and increasing lithium purity. As demand for lithium grows, advanced membranes will be essential to scaling lithium production while supporting environmental goals.