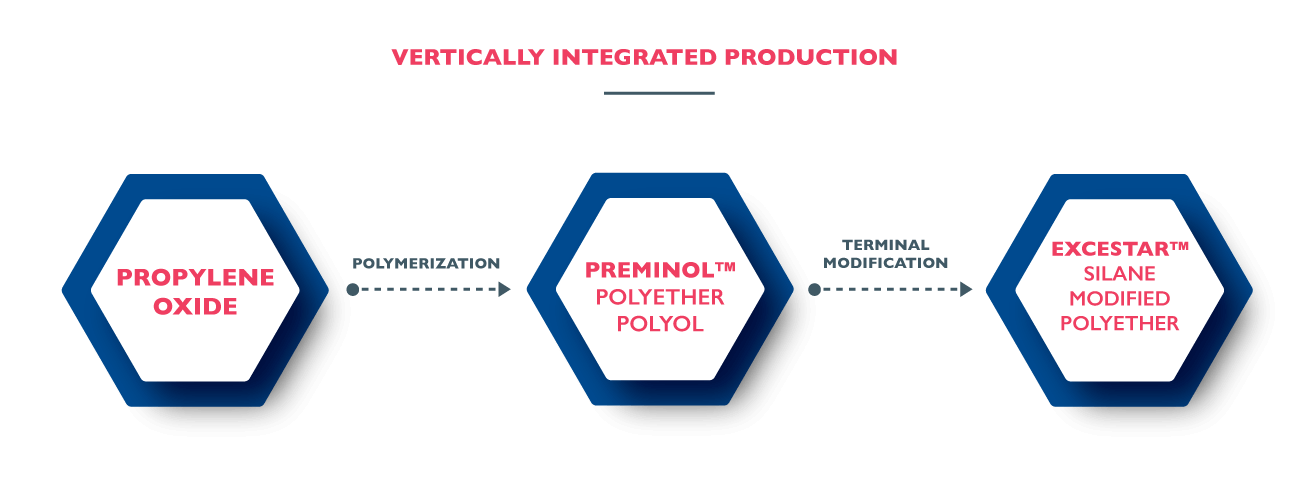

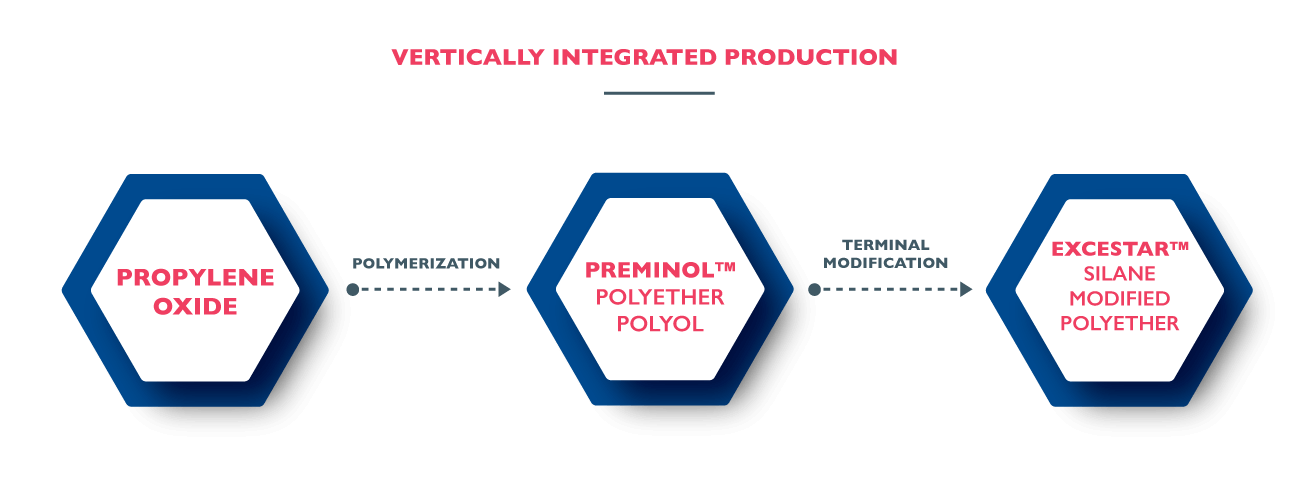

Polyether polyols are key components used in the production of polyurethanes. AGC produces polyether polyol (PREMINOL™) from Propylene Oxide. Subsequently, AGC uses PREMINOL to produce silane modified polyether (EXCESTAR™) as a moisture-curable polymer. These polymers, available in the Americas, have high molecular weights exceeding 10,000. AGC employs an advanced catalyst process which results in polyols with ultra-low monol content, and a narrow molecular weight distribution.

PREMINOL™ and EXCESTAR™ Properties

PREMINOL has ultra-low monol content, high molecular weight ranging from 3,000-18,000, and a narrow molecular weight distribution. This provides good mechanical properties, high flexibility, good durability and good workability for coatings, adhesives, sealants, and elastomer applications.

EXCESTAR is a liquid polymer for silane modified polyether sealants and adhesives. Its unique properties such as high flexibility, heat resistance, weatherability, and stain resistance, enable EXCESTAR to be applied in various markets including construction, industrial, and electronics. EXCESTAR products are toxic free, easy to use and the perfect choice where safety issues are a concern.

Portuguese, Brazil

Portuguese, Brazil

Clientes & Dúvidas Sobre Produtos: +55-11 99673-9340

Clientes & Dúvidas Sobre Produtos: +55-11 99673-9340